Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

robotic welding, helium leak tested vacuum component and fittings

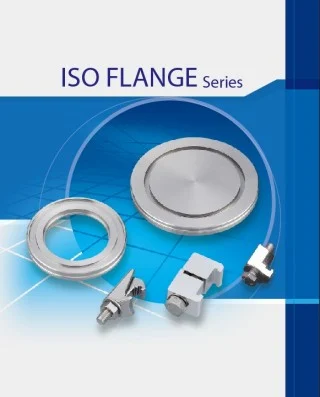

KF flanges, clamps, valves for all industry

Everfit Technology opens vacuum component market in Japan

Everfit Technology CO., LTD. (EFT)’s high-quality vacuum component and mainly engaged in professional manufacturer of stainless steel ferrules, components and fittings. Everfit Technology is famous for forge plant, welding technology and top quality control standards.

Today, Everfit Technology to open up the market in Japan and their stainless steel sanitary product selection has also widened from food suited vacuum components to the semiconductor industry, regardless of complex shapes, double contours or relatively large components.

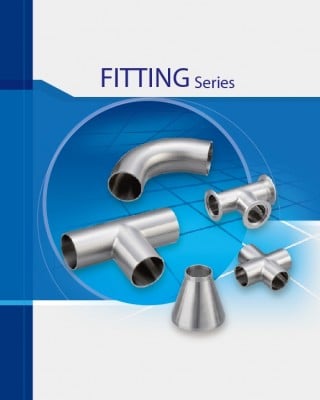

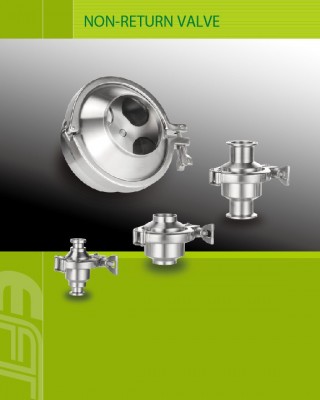

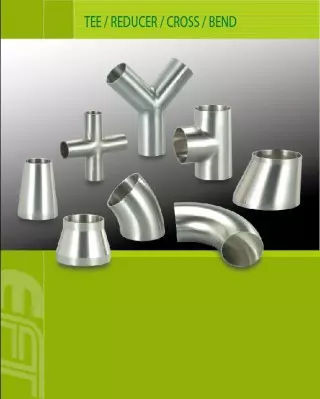

Vacuum components

Everfit Technology's Client in The World

Everfit Technology was providing the high quality vacuum flanges, components and fittings for many leading companies in the world. We has expanded our current plant to broaden services in OEM, ODM stainless steel components for various industries including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering. In addition, EFT also specializes in the manufacture of vacuum components to your precise requirements. Everfit Technology could meet the rigorous standards for every client in the world.

Why Everfit Technology for your vacuum component?

In many vacuum pipe fitting systems that convey highly abrasive materials, how much pressure a tube can handle, how long it takes for the material to go through, whether the vacuum pipe is 100% sealed and how precise welding is performed, all of these factors can be influential. There’s a constant need for technology improvement to manufacture hermetically closed stainless steel vacuum components, vessels, and tubes.

With years of vacuum component and fitting supply experience, Everfit Technology can create gauges and come up with innovative solutions to fit specific requirements. For example, to lower the cost, Everfit Technology designed a gauge that would allow three vacuum components to be tested at the same time. To avoid manual welding flaws, robotic welding is conducted. To perform better pipe tee pulling technology, a gauge is created to assist. There are many methods to detect and to ensure the process is perfectly done, and a team of elite engineers is the biggest asset at Everfit Technology.

Everfit Technology engineering team designs innovative gauges to meet high standard vacuum component requirements from clients

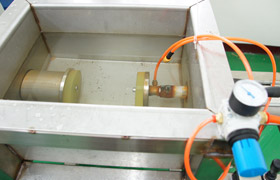

Leak and pressure testing equipment

Helium leak testing equipment to assure pipe tee quality

Leak detection is conducted after robotic welding. It is critical. Leaking toxic gas, rusted or otherwise damaged valves and fixtures can cause process failure and contamination. The helium leak testing equipment is equipped to test out each vacuum component they make. It is to assure that the vacuum fitting is perfectly done, inside and outside. It is also conducted in water to find the leak location.

Welding on vacuum component to increase its accuracy, repeat-ability, and throughput

Robotic welding to increase stainless steel vacuum component quality

Welding is critical during vacuum component’s manufacturing process. When the welding is imperfect, pores, worm holes, cracks or tears can occur, and for the semiconductor industry, this can lead to hazardous waste, toxic gas or fluid leakage. At Everfit Technology, robotic welding is replaced with manual welding; programmable robotic welding is performed to weld the part that needs to be seamless.

At the beginning, Everfit Technology was concerned with the cost. Later, they realized that a productive welding process actually lowers long term costs.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products