EVERFIT TECHNOLOGY CO., LTD.

One of leading stainless Steel Pipe Fittings Manufacturers for Your Industrial Vacuum Pumps

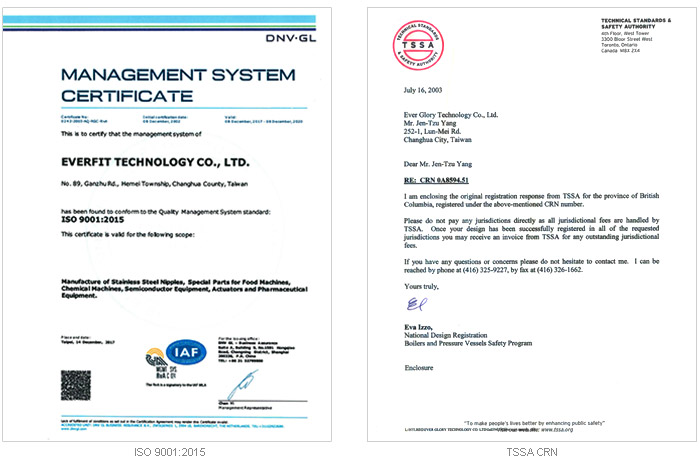

Everfit Technology CO., LTD. (EFT) is one of the stainless steel pipe fittings manufacturers based in Taiwan with over 36 years of experience. EFT provides 316, 316Ti stainless steel pipe fittings, pipe reducer, eccentric pipe reducer, vacuum pump, valve actuator - ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI certified.

- 1. Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- 2. Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- 3. EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- 4. Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- 5. Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- 6. Taiwan absolute vacuum components design winning Japanese trust

- 7. Pharmaceutical sampling valves supply

- 8. Germany, Japan, England imported valve actuator components

- 9. ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- 10. Vacuum component and fitting supply

- 11. Stainless steel forged wine valves

- 12. Multiport stainless steel valves from Taiwan

- 13. One-Stop forging service valve provider - EFT

- 14. EVERFIT TECHNOLOGY CO., LTD. (EFT)

- 15. Contact a vacuum component and valve supplier for processing equipment solutions

- 16. Send inquiry to a Taiwan vacuum component supplier

- 17. EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

1.Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

Your trusted PC pump supplier - Everfit Technology (EFT)

After two years and a long period of tests and trials, Everfit Technology CO., LTD. (EFT)'s mass production of progressing cavity pump parts was tested with zero flaws and 100% precision, which allowed them to become the only overseas supplier of this world-leading pc pump company from Japan. As for Everfit Technology, working with such a high standard client not only pushed them to upgrade their valve and vacuum component technology, but also encouraged RD engineering team to come up with innovative gauges and solution-solving capability.

The Japanese client manufactures progressing cavity pumps for environmental management systems, which are used for high viscosity, semi-solid and mixed materials that could be acidic and hard to transfer. The PC pump requires high viscosity tolerance and erosion-free flow, thus, 316 stainless steel is necessary. In addition, skillful valve and vacuum component technology is critical in order to fit other PC parts when conducting assembly and this is why their requirements are strict.

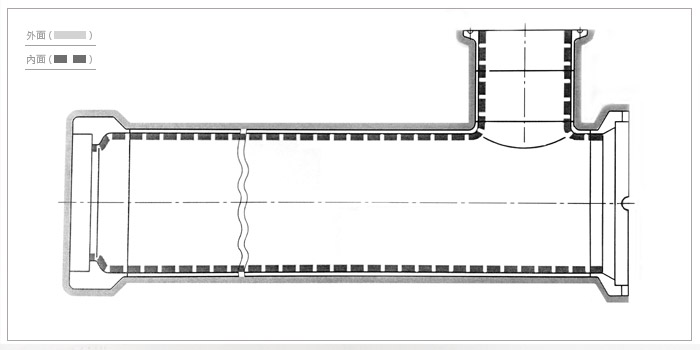

PC pump part design for a progressing cavity pump supply company from Japan

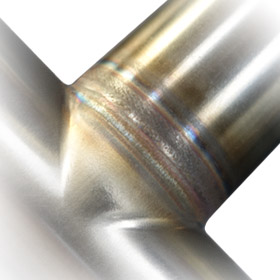

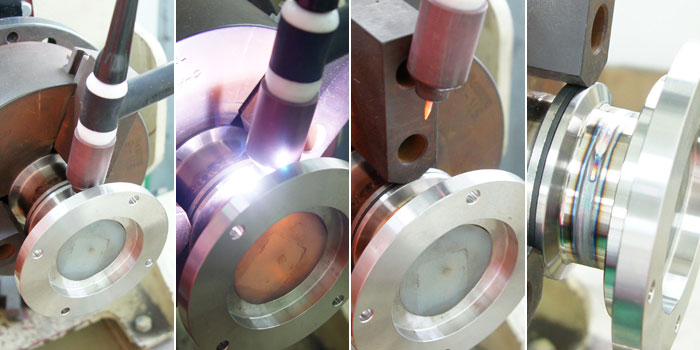

Multiple welding points plus rotary straightening to make perfect stainless steel PC pump - your trusted PC pump supplier - Everfit Technology (EFT)

After two years and a long period of tests and trials, Everfit Technology CO., LTD. (EFT)'s mass production of SUS 316 progressing cavity pump parts was tested with zero flaws and 100% precision, which allowed them to become the ONLY overseas supplier of a leading PC Pump, Dispenser and Dispenser HD provider from Japan. As for EFT, working with such a high-standard client not only pushed them to upgrade their stainless steel pipe fitting technology, but also encouraged RD engineering team to come up with innovative gauges and solution-solving capability.

SUS 316 progressing cavity pump part tested at the lab for its precision.

Stainless steel PC pump with multiple welding jobs

When engineers from Japanese PC pump company said it's impossible, EFT made it happen and the work was outstanding. Since then, the client 100% trusts EFT's pipe fitting production capability. The PC pumps were classified as rotary positive-displacement pumps consisting of a single eccentric screw. They provided a non-pulsating, metered conveyance, which was suitable for fluids with low fluidity. It's such a complex shape of pc pump. For the part that EFT was to manufacture, multiple welding jobs was needed in order to meet the specifications. How do you operate multiple welding jobs on a pipe without influencing each other, let alone other effects such as gaps, misalignment between the weld path and joint line, setup related variations, voids or holes in the weld path, mismatch between materials being joined, etc

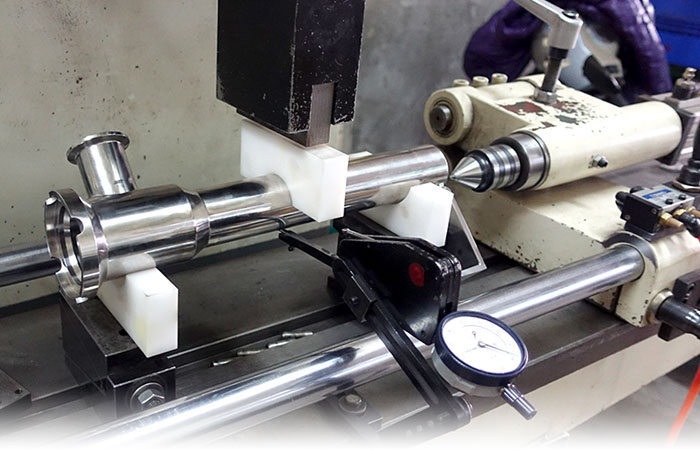

Success rotary straightening for exact tolerance on stainless steel PC pump

To achieve the rigorous standards requested from the PC pump client, EFT engineering team designed a gauge to support the welding. There were many amendments, yet, the concentricity was off. Later, an EFT engineer recommended pipe straightening, but the proposal was questioned. "The pc pump is too thin to operate straightening, the compressive force would cause more uneven and distortion on the surfaces, etc." Although doubted, EFT's engineer designed and built gauges – to support the stainless steel pipe - for the straightening process. While the pc pump was constantly rotating and straightening, a scale is steadily measuring its precision. As a result, the process delivered excellent straightness characteristics. The rotary straightening was capable of straightening pc pumps to exacting tolerances. The client was impressed with EFT's indomitable will to overcome the difficulties. Of course, the success allowed them to receive more pc pump orders after.

EFT's engineer designed and built gauges – to support the stainless steel pipe - for the straightening process.

Everfit Technology overcomes difficulties with innovative gauge and seasoned experience

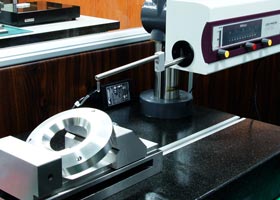

Roundness testers for PC pump's diameter inspection

There were times when things didn't go well with the manufacturing of pc pump parts. One time, the size of a part changed three days later, right before shipping. "We were shocked. How did that happen?" Was it because of the heat treatment or the milling process?" EFT's engineer recalled. After repeated testing, internal and external milling, and self-designed gauge testing, it worked! The shape stayed the same, firmly, even several days later.

For 316 stainless steel tube forging, EFT encountered difficulties in meeting the right size. With the client’s helpful advice, Everfit Technology was able to try out various methods and eventually achieved the size they wanted.

PC pump rigorous inspection from World-Class Japanese company

To the client, the goal was to assist Everfit Technology to produce 100% accurate mass production pc pump parts, in the form of specifications, material qualities, process procedures and inspection results. Thus, Japanese engineers and inspectors came to Taiwan numerous times, even the CEO of the company, which showed their endorsement of Everfit Technology's progressive cavity pump technology.

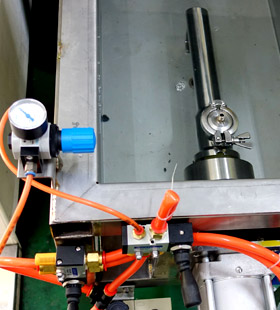

Leak and pressure test for vacuum component

To inspect, the Japanese client cut the pc pump tube in half to check out its longitudinal and internal welding quality. The tube should have low sulfur content and meet ASTM international standards. Height gauge was used to measure its core quantity; a set of roundness testers were applied to test the inside diameter; a gauge was utilized to test its shape and casing wear test was operated.

Everfit Technology's engineering team's great flexibility and seasoned valve and vacuum component experience allowed them to develop various jigs in order to test each pc pump’s size. Meanwhile, the jigs to avoid the influence of heat treatment and machining were developed. Overall, the pc pump was made with no cracks, no pin-holes, and 100% smoothness of 316 tubes with exact size.

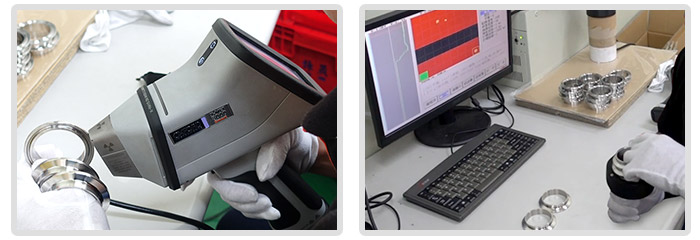

"One time, our product was rejected for impurity 316 stainless steel after the client did a metallurgical analysis; since then our material inspection is required with tougher rules. It's a learning experience for us," said Sunny Huang, the sales manager of Everfit Technology.

Roundness testers for PC pump's diameter inspection

Everfit Technology - Your Trusted PC Pump Supplier

From the internal welding quality, the speed of a knife spin, heat treatment, machining, tooling and finishing, each step was watched closely by the client. The Japanese engineer suggested their manufacturing methods and Everfit Technology's RD team input their knowledge to make pc pump part meet all the requirements.

Recently, Everfit Technology has been receiving various shapes of pc pump parts from the client, which has been challenging in many ways, regardless of mold making, gauge designing, machining, and testing, etc. However, Everfit Technology was able to tackle the dilemmas and strive for the best results.

Vacuum components

2.Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

Starting from manufacturing food grade 304 stainless steel pipe fittings in 1988 at a small factory, EFT (Everfit Technology CO., LTD.) was one of very few manufacturers in Taiwan. Over the last 40 years, EFT had moved to a 5,500-meter plant due to the ramp up of their business and the workpiece's increased challenge from clients. As client's vacuum component requirement complicity increased, EFT's machining and inspection process upgraded from time to time.

Robot Arm High Technology Pipe Fitting Production

There's no more human error or manual flaw with robot arm processing.

Between the robot arm and adjustment of fixture and jig, EFT is moving toward to becoming a manufacturer of pipe fittings with high technology. With the automatic robot arm, the production cost is lowered, quality is controllable, and production capability is highly effective. There's no more human error or manual flaw.

Unlike before, each product is delivered and taken by hand. It may seem simple, but it makes a big difference when having a robot arm that is capable of produceing 20,000-30,000 pipe fitting a day. Time is money. Thus, EFT purchased a robot arm to increase the product quality and production capability. With robot arm's assistance, the employee is responsible for setting up the PLC, checking the product, changing knife/fixture and inspection.

Robotic arm has been assisting EFT meeting deadlines with great precision and accuracy, thus providing improved, consistent product quality.

With the automatic robot arm, the production cost is lowered and quality is controllable.

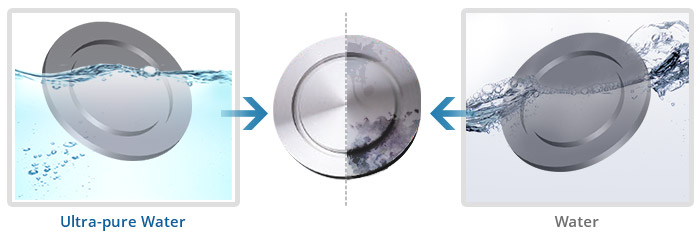

Ultra-pure Water System - Delivers the Cleanest Pipe Fitting

When the pipe components are delivered to semiconductor or food processing company's sites, each part has to be extremely clean without any microscopic dust. To do so, EFT bought a set of Ultrapure Water Systems to produce the finest water. The system is used in industries such electronics for IC manufacturing, a pharmaceutical for medicine production, cosmetics and food production.

During the machining process, dust, grease, and steel filings can remain attached to the vacuum pipe fittings. To solve the problem, there's a procedure: first, alkali cleansing, then acid treatment, followed by purified water washing, and the last would be hot air blow dry. It is to make sure the client receives the best of product, 100% clean without any particles on the surface. To see more details of Ultrasonic and RO Water Self-Cleaning Process .

Ultrasonic and RO Water Self-Cleaning System

Stainless steel filings, grease stains, oil stains or water stains are removed after using ultrasonic and RO water self-cleaning system, and the labor cost is lowered.

Automatic Stainless Steel Detector before Vacuum Component Delivery

When stainless steel shipments arrive, 304 or 316 are marked by color using laser guns. Before shipping to clients, every vacuum component is checked to double-check the accuracy of the steel. It is a system developed through collaboration between EFT and the equipment company. The goal is to assure 100% accuracy of steel.

The 304, 316 stainless steel comes test machine comes with two molds, each time you put a fitting on the tool, it makes a distinct sound when it's not what the parameter is set for. Because of this equipment, 304 and 316 are detected quickly, which saves time and cost. Since then, metallurgical analysis always resulted in precisely what material is expected.

304 and 316 stainless steel detector system is designed to ensure its material accuracy.

ISO 9001:2015 Certificate

EFT has been gaining recognition internationally because of their high-quality pipe fittings, even though buyers came from all over the world with high standards. Tasks like multiple welding on a single cavity (PC) pump, pipe tee with a particular pulling technique, valve component that needed special machining using CNC and milling machine, cleanroom process , 316L eccentric reducer weighted 30 kg (6 inches) that required CNC machining and non-central valve components forging , valve actuator spring that required long-term test, or vacuum component requested to meet ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI criteria.

EFT's vacuum components are sold worldwide, including in Germany, the U.S., the U.K., France, Japan and Israel. Industries ranging from semi-conductor, pharmaceutical, environmental management system, food processing to biotechnology, which requires seamless, purified, precise and particle free components. To meet international buyer's particular specifications for steel fittings, stainless steel 304 and 316 Ti was imported from Italy, France, and Korea to improve its machining performance. 316 Ti is cut 100% accurately by new CNC automatic circular sawing machines because of its material characteristics. Welding precision was taken care of by robot arms. Equipment was purchased to improve machining performance. Software, gadgets, and molds were developed to speed up the material test and production capacity. Overall, the engineering team was terrific, averaging over 20 years' engineering experience that has allowed each engineer to come up with solutions with great flexibility.

Complex shapes, double contours or relatively large components were challenging, but EFT resolved problems step by step with seasoned experience. Whatever it takes for EFT to achieve client's goals, such as manufacturing 316Ti ferrules for a fluid connector, eccentric reducer for pharmaceutical's medicine process, robotic welding for pipe tee, valve component that involves tough machining job for the non-central angle stub flange section, etc., EFT's relentless hard work and the zero tolerance on each pipe component's specification is the main reason for today's success.

Large size stainless steel 316L, 30kg and size 6 inches eccentric reducer is built meeting ASME BPE standards.

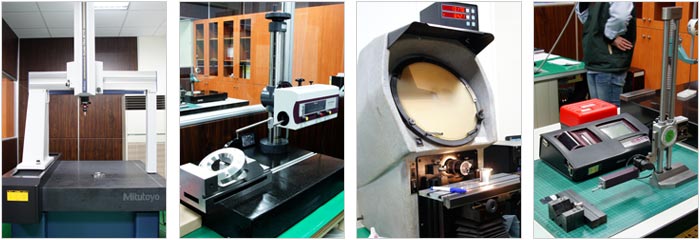

Accuracy is always the objective, regardless of whether it's for tooling and machining process or product inspection. At the lab, test equipment is provided, but the precision would depend on the standard of machinery. Beginning with food-grade 304 pc pump part to BPE semiconductor piping and today's 316Ti stainless steel pipe fitting for oil piping, for a component that is large, has eccentric circles or with an internal diameter, the regular testing equipment can no longer fit for test requirements. In 2017, procurement was made to improve the quality of stainless steel fittings, whether its ferrule, vacuum flange, compressible bellow connection, pipe fitting, adapter or diaphragm valve, the precision is assured. EFT is one step further toward to meeting ISO2015 international standards.

IM Series Instant Measurement System - 100% Pipe Fittings Specification Precision

IM Series Instant Measurement System

Every test machine has its functionality; comparator is suitable for outside diameter, height gauge works for inner and outer diameter, roundness tester for inner diameter, and coordinating measuring machine is for stainless steel flange. Instead of using ruler and projector, which takes time to get it done, EFT purchased an IM Series Instant Measurement System to speed up the process, as well as to increase its accuracy.

Normally it takes 3 minutes to finish the measurement for one product. With the regular IM Series Instant Measurement System, once the pipe fitting is scanned and the parameter is set, the scanning takes less than 10 seconds. The equipment measures up to 99 dimensions in seconds, including parallelism, concentricity, roundness, straightness, true position, full profile and more. ( read article: World Standard Vacuum Component Plant To Meet Your Needs)

3.EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds german leading fluid connector manufacturer's expectations

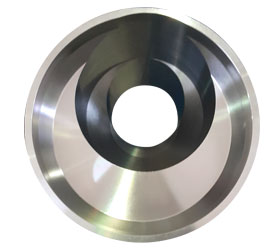

316Ti (ASTM, DIN 1.4571) ferrules for heavy-duty industrial applications.

Everfit Technology CO., LTD. (EFT) is a stainless steel pipe fitting manufacturer that has been supplying 316L stainless steel hydraulic hose couplings and compression fittings to a German leading stainless steel fluid connector manufacturer for over ten years. Two years ago, the client requested 316Ti (ASTM, DIN 1.4571) ferrules for heavy-duty industrial applications. To meet the deadline, flexibility and innovation were needed.

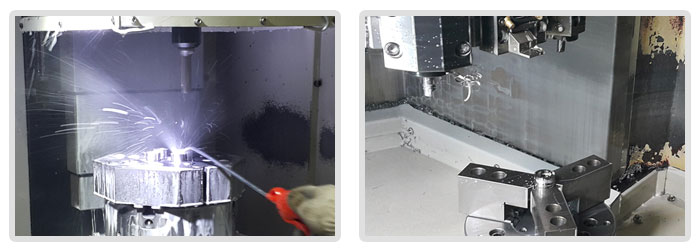

It was a fuel pressure's fitting in the auto parts. At EFT, during the machining process, equipment was relentlessly tested by trial and error, including automatic circular sawing machines, CNC horizontal boring machines, and CNC lathing machines. Also, suppliers' 316Ti was experimented during machining practices to find out which material has the best performance. All the actions taken were to lower the fatigue strength on 316Ti.

For instance, automatic circular sawing machine and 316Ti boring machine were purchased, CNC lathing machine designed with additional functions, cutter and gauge designing for a machining process, and 316Ti material supplier sourcing. In general, 316Ti machining technique was regularly modified based on the outcome. In the end, steel scrap's amount was reduced due to the processing accuracy, productivity was improved, the ferrules were perfectly delivered to the client, and EFT has proved their highly skillful engineering technology to accommodate each client's standards.

316Ti material from overseas

316Ti material from Italy for ferrule manufacturing

EFT purchased material from suppliers in Italy, France, and Korea to improve titanium machining performance.

Because of titanium's distinct properties, this has further complicated the machining process. 316Ti can be strongly influenced by even a slight variation among elements, though all are named 316Ti stainless steel. Without compromising client's fitting quality, EFT insisted on using the titanium alloy that performs the best, regardless of turning, boring, milling, drilling, reaming, tapping, broaching, shaping, shaving, grinding, etc.

CNC Automatic Circular Sawing Machine for cutting accuracy.

CNC Automatic Circular Sawing Machine to Cope with Rigid Titanium Bars

With titanium bars, the force and velocity from the cutting machine determines the cutting accuracy. When it cuts imperfectly, the subsequent procedures - drilling and lathing – are influenced. Therefore, EFT's purchased four new CNC automatic circular sawing machines to increase titanium bar's cutting certainty.

Since then, every cut bar has the same length, perfect flatness, and more importantly, the rest of 316Ti machining productivity is improved.

CNC Boring Operation Machine Leads to High-Performance Lathing Process

With no high-efficiency bore machine, incorrect boring size leads to more machining workload. At EFT, each 316Ti stainless connector is bored with a gauge to enhance its drilling efficiency. Plus, with CNC vertical boring operation machine’s quality boring job, every piece is drilled with the correct size, straightness, and concentricity.

CNC lathing machine leads to High-Performance of lathing process

To shape 316Ti ferrules, cutting, sanding, knurling, and drilling with high precision wasn't easy; there were many worn out knives, titanium steel scrap clustered and dragged machining speed. All these factors had resulted 316Ti fitting with flaws, and to make it right, the engineering team came up with some solutions. By enlarging the pump size and increasing cutting fluid's amount from 15% to 70%, the milling cutter's heat generation was prevented. And because of the high-speed operation, steel scrap was removed fast, which has allowed the lathing from a smaller hole and therefore was more effective. The cutter, after studies, were custom-made to handle titanium's tough surface.

316Ti ferrule's complex machining process is overcome by talented EFT engineering team.

Everfit Technology CO., LTD. (EFT) – custom made your 316Ti stainless steel components to meet impossible

Although challenging, the hydraulic hose couplings and compression fittings were delivered on time, and the quality was impeccable. And because of the high performance of complex machining work, EFT was able to expand their 316 titanium part services in Germany along with France, Israel, and Japan. EFT's technology and know-how, as well as the broad range of services in various industries, allows them to be continuously reached by world-class customers.

Everfit Technology CO., LTD. – stainless steel pipe fitting expert

Based in Taiwan since 1976 and specialized in manufacturing concentric and eccentric reducers, ASME BPE, pipe tees, BPE fittings, PC pumps, vacuum components, valve actuators and valves, and meeting DIN / EN / SAE / BS & standards with stainless steel 304, AISI 316 and 316Ti. EFT is well-known for achieving the impossible; their high-passion engineering team plays an important role overall.

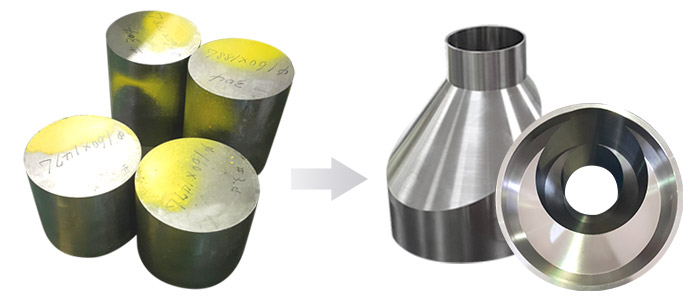

EFT's concentric and eccentric reducer machining solutions for a German pharmaceutical client

Rather than using a lathe machine to conduct machining process on concentric and eccentric reducers, which are stainless steel 316L, weight over 30kg and size 6 inches, EFT switched to CNC milling machine with integrated solutions to achieve the German pharmaceutical client's requests and also meet ASME BPE standards.

Stainless steel 316L, 30kg and size 6 inches eccentric reducer is built meeting ASME BPE standards.

Unlike before, concentric and eccentric reducer can be machined with stainless steel pipes and tubes by applying forming and trimming technologies. Based on ASME BPE -2012, steel bar becomes mandatory for making pipe fittings. Stainless steel bar requires different machining solutions, since lathe machine just can't achieve the goals. Particular for the client's product is that a 6in. 316L eccentric reducer's thickness is uneven, the steel is tough for processing, the machining time is long due to low speed and constant feed rate, and the generated centrifugal force also makes the result unreliable.

Eccentric reducer is manufactured by a group of elites with innovative technology.

In the beginning, EFT designed and built a gauge to support reducer fitting's machining process from lathe machine. However, cutting knives got worn out, and machines broke down for days. It took five days just to finish one, let alone 100 of them! EFT needed to increase the productivity.

As a result, to facilitate concentric and eccentric reducer's production speed along with high precision, EFT engineering team decided to use 100% automatic CNC milling machine, incorporated with a specially designed cutter to handle the concentric and eccentric reducer's machining operation. With the whole eccentric reducer sitting on the machine platform, centrifugal force issue is eliminated, the processing speed is faster, and the product accuracy is 100%. The large size eccentric reducer's machining process is no longer an issue, and they are capable of manufacturing size 1/2", 2/3", 1", 1.5", 3", 4", 6", and more. EFT's industrial standard concentric and eccentric reducer allowed them to sell in the semiconductor, pharmaceutical, and food and beverage industries with solid reputation.

To make stainless steel fittings with 100% precision, gauge and mold design are critical. At EFT, they are constantly delivering solutions to meet clients' standards.

4.Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

Pipe tee supply - 20 times cheaper with sophisticated pulling technology

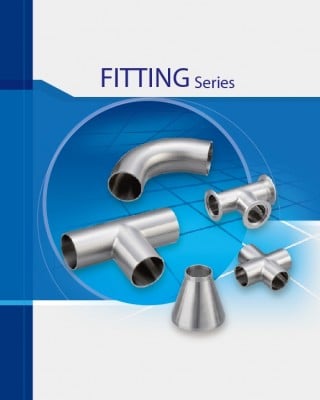

Sanitary tee with perfect circle using pull technology

Because of Everfit Technology CO., LTD. (EFT)’s pipe tee pulling technology, making an impeccable sanitary tee that is made of tube 316, with low sulfur content, manufactured to stringent ASTM A270-S2 specifications with lowered cost is possible. As a result, a world leading vacuum pipe fitting company from Israel made an expanded procurement with Everfit Technology to enhance their cooperative relationship.

The client was a worldwide leader in the manufacturing of process stainless steel fittings for biopharmaceuticals and semiconductors; and a leading manufacturer of sanitary valve & actuators for food and cosmetics industries. Their requirements were strict.

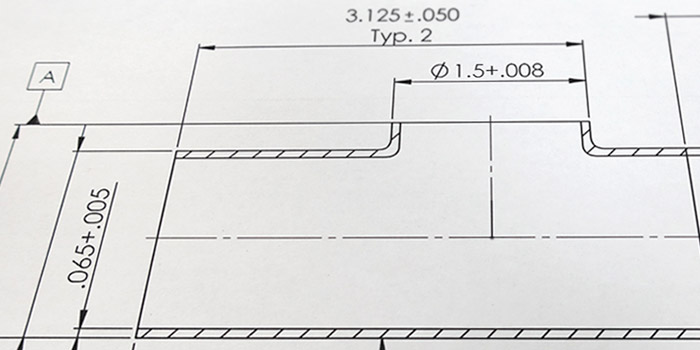

Specification requirements of T-shaped pipe tee from client with strict standards

Pipe Tee's Manufacturing Plan to Achieve 100% Perfection

Robotics welding on T-shaped pipe tee to increase its accuracy, repeat-ability, and throughput

Everfit Technology’s engineering team delivered a plan regarding a pipe tee's circularity, pulling percentage, mold design and welding method after receiving an inquiry. Robotic welding is applied to assure the fluid in the stainless steel fitting flows smoothly. Moreover, pipe’s pulling percentage is calculated to achieve correct thickness and roundness, and the mold should be able to clamp precisely to assure its pulling performance.

Pipe-Pulling stainless steel tee – reasonable priced and beautifully made

Rather than using hydraulic tee forming technology, which is expensive because of the cost of forming machine and mold-making, Everfit Technology decided to use the pipe-pulling method, which also includes mold-making and robotic laser welding. Pipe pulling technology is relatively hard to do; elegant mold design and pipe pulling operation experience and skills are required. If it fails, buckling and splitting could occur.

Pipe-pulling requires technology that depends on the configuration of the mold, the pull force, and the pipe condition; it took rigorous trials to make it work.

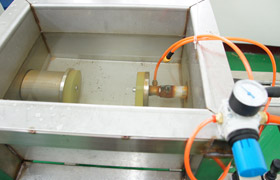

helium leak test

-

The Israeli client asked for 20 sample products. Each t-shaped tee had to be:

- Tube 316L with low sulfur content (0.005-0.017%). In accordance with ASTM A270-S2.

- Longitudinal and circumferential scratches are not allowed.

- Welding type:tig/laser/robotic welding

- The wall thickness across the seam should not deviate more than ±0.02 mm with respect to the nominal wall-thickness of the tube.

- The seam should be uniform, having "full penetration" with no "under-cut", "protrusions", etc.

- The seam should be free of "oxidation" and "porosity", with no evidence of "lack of fusion", or "incomplete fusion".

- The seam should be "internally bead rolled" in order to have a uniform wall-thickness across the weld area.

Stainless steel pipe fitting that is 20 times cheaper

Normally, the only method to build high-quality sanitary tee is to use one-step forming technology. The process makes perfect stainless steel tees; however, it is very costly. The equipment and mold making could cost millions, let alone one mold can only produce tee pipes with one size.

Everfit Technology's piping and plumbing fittings were able to meet the Israeli client's needs for the pharmaceutical industry. Everfit Technology’s T-shaped pipe tee meets roundness tolerance, and both outlets are 90 degrees connected to the main line. The penetration welding was conducted by a robot that leaves a smooth surface and met ASTM standards.

It was challenging, but Everfit Technology was ready. Years of serving international clients has allowed them to have the flexibility to come up with strategic solutions, such as mold and gauge design, in order to achieve requirements of the customer.

T-shaped pipe tee

Everfit Technology CO., LTD. – A professional stainless steel welding tee supplier from Taiwan

vacuum component precise welding

Sometimes, it is all about the timing; the requirement came while Everfit Technology was working on bathroom faucet's development; therefore, everything was ready.

Combining years of vacuum component experience, existing equipment, matured mold and gauge design technology, Everfit Technology was able to make pipe fittings meeting the client's rigorous standards. And the most important thing was that the cost of pipe tee was lowered. The manufacturing of stainless steel sanitary fittings not only allowed Everfit Technology to open up a new market, but it is also cost-saving without sourcing elsewhere.

5.Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

Everfit Technology opens vacuum component market in Japan

Everfit Technology CO., LTD. (EFT)’s high-quality vacuum component and mainly engaged in professional manufacturer of stainless steel ferrules, components and fittings. Everfit Technology is famous for forge plant, welding technology and top quality control standards.

Today, Everfit Technology to open up the market in Japan and their stainless steel sanitary product selection has also widened from food suited vacuum components to the semiconductor industry, regardless of complex shapes, double contours or relatively large components.

Vacuum components

Everfit Technology's Client in The World

Everfit Technology was providing the high quality vacuum flanges, components and fittings for many leading companies in the world. We has expanded our current plant to broaden services in OEM, ODM stainless steel components for various industries including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering. In addition, EFT also specializes in the manufacture of vacuum components to your precise requirements. Everfit Technology could meet the rigorous standards for every client in the world.

Why Everfit Technology for your vacuum component?

In many vacuum pipe fitting systems that convey highly abrasive materials, how much pressure a tube can handle, how long it takes for the material to go through, whether the vacuum pipe is 100% sealed and how precise welding is performed, all of these factors can be influential. There’s a constant need for technology improvement to manufacture hermetically closed stainless steel vacuum components, vessels, and tubes.

With years of vacuum component and fitting supply experience, Everfit Technology can create gauges and come up with innovative solutions to fit specific requirements. For example, to lower the cost, Everfit Technology designed a gauge that would allow three vacuum components to be tested at the same time. To avoid manual welding flaws, robotic welding is conducted. To perform better pipe tee pulling technology, a gauge is created to assist. There are many methods to detect and to ensure the process is perfectly done, and a team of elite engineers is the biggest asset at Everfit Technology.

Everfit Technology engineering team designs innovative gauges to meet high standard vacuum component requirements from clients

Leak and pressure testing equipment

Helium leak testing equipment to assure pipe tee quality

Leak detection is conducted after robotic welding. It is critical. Leaking toxic gas, rusted or otherwise damaged valves and fixtures can cause process failure and contamination. The helium leak testing equipment is equipped to test out each vacuum component they make. It is to assure that the vacuum fitting is perfectly done, inside and outside. It is also conducted in water to find the leak location.

Welding on vacuum component to increase its accuracy, repeat-ability, and throughput

Robotic welding to increase stainless steel vacuum component quality

Welding is critical during vacuum component’s manufacturing process. When the welding is imperfect, pores, worm holes, cracks or tears can occur, and for the semiconductor industry, this can lead to hazardous waste, toxic gas or fluid leakage. At Everfit Technology, robotic welding is replaced with manual welding; programmable robotic welding is performed to weld the part that needs to be seamless.

At the beginning, Everfit Technology was concerned with the cost. Later, they realized that a productive welding process actually lowers long term costs.

6.Taiwan absolute vacuum components design winning Japanese trust

Eight-year excellent vacuum component work for a Japanese company

EVERFIT TECHNOLOGY CO., LTD. (EFT) has served a Japanese company well with their high quality semiconductor vacuum component for eight years. Since Japanese companies are famous for being meticulous and strict, how did EFT meet their requirements and survive in the competitive market these days?

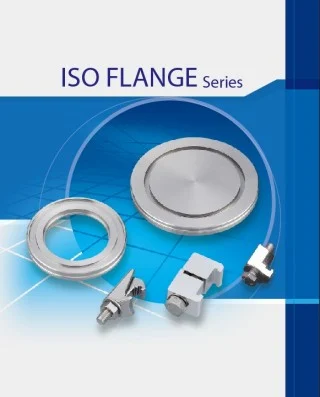

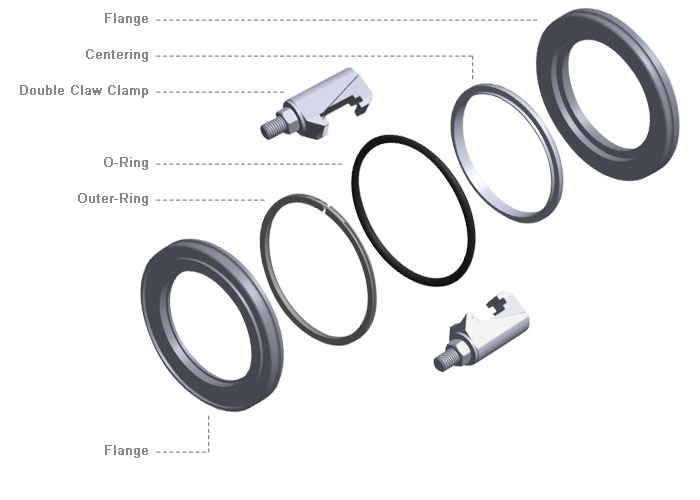

Semi-conductor stainless steel vacuum components & Fittings requirement

For the semiconductor industry, semiconductor device vacuum component is rigorously required to be vacuum engineered in order to process in an aseptic environment. Since toxic gases are applied during process, sterilized stainless steel parts such as flanges, adaptors, clamps, bellows and vacuum fittings should be ISO certified. In addition, pipe fittings should be seamless; assembly, cleaning and packaging should be done in a clean room.

For food processing equipment, pipes and fittings have to allow high acidity. However, when manufacturing semiconductor devices, processing equipment that has high pressure tolerance and zero defect production is critical. For excellent aseptic equipment, it would not only increase equipment efficiency but also reduce maintenance.

Japanese companies tough requirements for vacuum Components & fittings

It is frequently said that Japanese companies are very strict about quality, and FET experienced that themselves. When the Japanese company was searching for a partner to expand their production capability and to broaden the market, their specific requirements resulted in lots of manufacturers being turned down. "They requested stainless steel vacuum fitting samples, and when they flew over to check out the vacuum component samples, they had markers in hand to circle the dust." the vice president Tom Chang recalled. As a result, the company visited EFT five times before making the orders. For the half year, they were just reassuring EFT's capability, and their picky requests made EFT pursue the best. The two companies now cooperate on vacuum fittings, including welded bellows, formed bellows, flexible tubes, etc.

To control the vacuum components & fittings quality, all stainless steel coming from Taiwan's largest steel companies, namely Gloria Material Technology Corporation and Walsin Lihwa Corp. includes material reports, and when they arrive at the plant, all stainless steel is tested using SPECTRO iSORT. EFT has expanded their plant by establishing a mold design and development division. The semiconductor vacuum component mold design team utilizes the latest technology in hardware and software to design molds. With plenty of mold design experience, every mold has improved cycle times and ultimately keeps costs down. EFT has procured more machines to increase the production capability, including pressing machines, sawing machines, drilling machines, CNC machines, ultrasonic and RO water cleaning machines and a custom made non-oxygen welding machine.

The stainless steel vacuum component quality is assured by executing first production examination, every two hours' onsite inspection by supervisors, lab testing using suitable testing equipment including Crysta-Plus M 776, Mitutoyo contracer contour measuring instrument, optical comparator and TECLOCK sylvac. EFT also implemented a class 10,000 clean room to meet vacuum components' 100% aseptic environment requirements.

ISO Flange connection with Clamp

Cleanroom (class 10,000) For High Standard Vacuum Component:

Class 10,000, ISO certified cleanroom for hygienic vacuum components

For semi-conductor, pharmaceutical, bio-technology and food processing industries, stainless steel vacuum components are required to be purified and particle-free. Therefore, EFT has set up a cleanroom that is equivalent to ISO standard. In the cleanroom, vacuum fittings will be cleaned; the assembling and packaging processes will be done in the room before leaving the room.

Eventually, the Japanese company was really satisfied with EFT's quality work, and every month they have been receiving orders from them over the past eight years. Because of the high quality stainless steel vacuum fittings that EFT fabricated for them, it also attracted other Japanese and Taiwanese semiconductor companies' attention. One of the world's leading semiconductor device suppliers from Taiwan asked EFT to become their vacuum fitting OEM supplier after several visits. Later, EFT has broadened their service range from OEM, ODM to custom vacuum component and process equipment supply.

![]() The Japanese company was established in 1984. They are specialized in processing piping design, construction, process equipment manufacturing including welded bellows, vacuum pumps, vacuum component and accessories supply.

The Japanese company was established in 1984. They are specialized in processing piping design, construction, process equipment manufacturing including welded bellows, vacuum pumps, vacuum component and accessories supply.

7.Pharmaceutical sampling valves supply

Strong sample valve component machining skills winning U.S. client's heart

In Taiwan, the most complicated sampling valve component machining service was conducted by EFT; their state-of-the-art sampling valve components helped convince a U.S. process equipment supplier to double their orders and increase payment. Due to the sampling valve component business opportunity, EFT not only took a big step on enforcing their machining skills, they also expanded their market in the pharmaceutical industry worldwide.

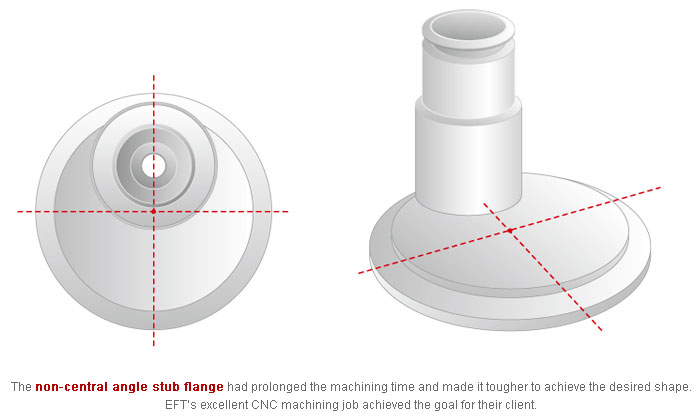

Difficult Machining Jobs for Pharmaceutical Sampling Valves

When FET received the sampling valve component inquiry, they realized it wasn't an easy job. It was a component for vaccine processing equipment that requires specific CNC and milling machining processes due to its specific design. It has a stainless steel flange with a stub welded near the central point. However, the non-central angle stub flange had prolonged the machining time and made it tougher to achieve the desired shape. It was time-consuming and difficult! It took hours to complete one, which made the cost of production go way up. Nevertheless, when the U.S. company's engineer saw the work, they were thrilled. After the first shipment, EFT received a new procurement for double the amount of sampling valve components, and the U.S. company was willing to pay more for the high performance. EFT engineers have been finding solutions to cut down the product costs.

Forged stainless steel sampling valve component

While some valve suppliers are still using sand casting or other casting methods to fabricate sampling valves, EFT had already started using stainless steel to forge the components for their solidness and product qualities. When manufacturing a sampling valve for a vaccine production facility; every pharmaceutical company requires a precise sampling valve to avoid leaking or contamination accidents, only stainless steel forging can create the densest one. EFT purchases their stainless steel directly from steel companies in Taiwan to ensure their 100% purity.

![]() The U.S. company is a manufacturer of hygienic and extreme clean stainless steel components for use in the biotechnology and pharmaceutical industries. Their stainless steel products including processing equipment for fluid line heat exchangers, sample coolers, SIP-ABLE sample valves, angle bleed and sample valves, inline bleed and sample valves, tee block bleed and sample valves, thermowells, stability test valves, co-axial tube, dip tubes, instrument tees & CPM's, custom and standard filter housings.

The U.S. company is a manufacturer of hygienic and extreme clean stainless steel components for use in the biotechnology and pharmaceutical industries. Their stainless steel products including processing equipment for fluid line heat exchangers, sample coolers, SIP-ABLE sample valves, angle bleed and sample valves, inline bleed and sample valves, tee block bleed and sample valves, thermowells, stability test valves, co-axial tube, dip tubes, instrument tees & CPM's, custom and standard filter housings.

8.Germany, Japan, England imported valve actuator components

Bearable valve actuator for your butterfly valves

Actuator with control box + butterfly valve

EFT's high quality spring valve actuator can withstand a harsh test conducted by a French company. The test lasted three months!When the French company received the valve actuator samples, they spent three months to test the springs 2,000,000 times. The French company is also a stainless steel valve, pipe fitting and processing equipment supplier in France, why do they need EFT to fabricate spring valve actuators for them? It is because the French company knows that EFT has the capability to achieve their specific manufacturing process requests, and EFT's complete production line with a newly built cleanroom (class 10,000) is also an advantage.

Why is valve actuator's spring important?

Valve Actuator is commonly used as a mechanism to output force and stroke, and the ability is different based on different factors, including the diameter and the pitch of the spring or the dimension of the cross, section of the spring wire, etc. EFT's spring valve actuator provides excellent control of the valve position and speed during valve opening and closing events.

Germany and Japan imported valve actuator components

For a valve actuator, normally there are more than twenty components, and the spring is one of them. Their insistence on supplying valve actuators encouraged EFT to buy springs from Germany and Japan with test reports provided.

French Company Valve Actuator Manufacturing System Applied

For valve actuator's production process, the French company recommended alternative methods. Even though the extra work processes added to the cost, EFT treated it as a learning opportunity. By adapting their fabrication system, EFT delivers state-of-the-art valve actuators. As a result, due to the high quality of valve actuators, EFT now is selling to various countries worldwide.

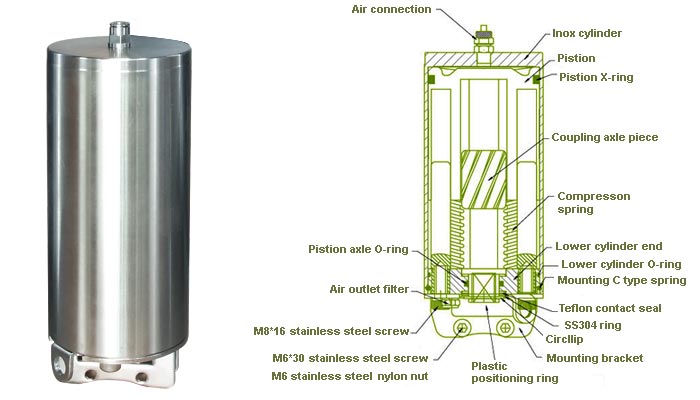

S1 Actuator

| Air/Spring Actuator simple or double effect for Ø25(1") to Ø76(3") butterfly valve | |

|---|---|

| Shut-off time | 1.5 seconds |

| Weight | 3.7kg |

| Power | 4M/Kg at 5 bar compessed air. |

| Max. torque | Max. torque 20N/m |

| Consumption | 0.266 liter at 5 bar |

| Material | Stainless steel AISI 304 |

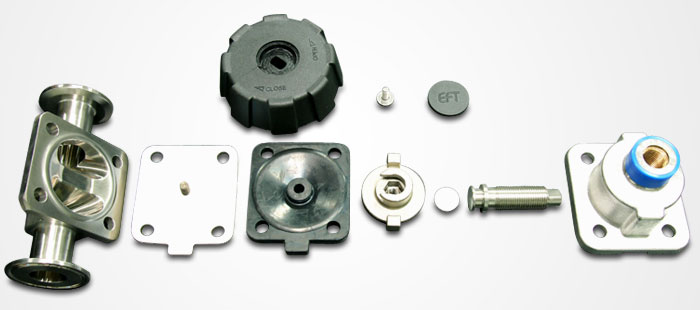

- S3 Actuator

- Plastic cover

- Inox cylinder

- Pistion

- Pision X-ring

- Coupling axle piece

- Compresson spring

- Lower cylinder end

- Lower cylinder O-ring

- Mounting C type spring

- Teflon contact seal

- SS304 ring

- Circlip

- Mounting bracket

- Plastic positioning ring

- M6*30 stainless steel screw

- M6 stainless steel nylon nut

- M8*16 stainless steel screw

- Air outlet filter

- Pistion axle O-ring

- Air connection

- Pistion stem O-ring

- Pistion Stem

- Stem plastic cover

| Air/Spring Actuator Simple or Double Effect for Ø25(1") to Ø76(3") Butterfly Valve | |

|---|---|

| Shut-off time | 1.5 seconds |

| Weight | 3.7kg |

| Power | 4M/Kg at 5 bar compessed air. |

| Max. torque | Max. torque 20N/m |

| Consumption | 0.266 liter at 5 bar |

| Material | Stainless steel AISI 304 |

| Cover | Plastic |

EFT choices the best suppliers for your valves and vacuum components

Walsin Lihwa Corp. is a leading manufacturer of bare copper wire, wire and cable, and specialty steel in the Greater China region, and has also successfully expanded into the high-tech industry and become an international enterprise with green energy, photovoltaics, real estate, and trade operations.

Gloria Material Technology Corporation (GMTC) is the first specialty steel manufacturer in Taiwan to engage in the manufacture of special alloy materials.

Sanyo Special Steel Co., Ltd. is the only domestic manufacturer specializing in special steel that has tube plants, manufacturing bearing steel, engineering steel, and stainless steel, as well as superalloy tubes and other seamless steel tubes/pipes.

POSCO became the top of the world steel industry in 1998. The year 1999 was witness to a total revamping of the Company's overall processes in procurement, production, and sales, and the construction of an integrated digital system.

Yeun Chyang Industrial Co., Ltd. is the biggest service center for stainless steel. Their products are: stainless steel coil, stainless steel sheet, stainless steel plate, stainless steel welded pipe, stainless steel welded tube, stainless steel angles, stainless steel flat bar, and stainless steel U channel

FROCH ENTERPRISE (FROCH) is established in 1984, FROCH has been working relentlessly in making quality stainless steel pipes, tubes, sheets, and coils, and is a specialized manufacturer for stainless steel tube and pipe.

9.ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

Medicine processing equipment tested by famous pharmaceutical companies in England, Germany and Japan

EVERFIT TECHNOLOGY CO., LTD. (EFT) sanitary diaphragm valves were tested at the pharmaceutical companies, and the companies were applying cleaning-in-place (CIP) and sterilization-in-place (SIP) self cleaning and sanitation systems in England, Germany and Japan. They are world leading pharmaceutical companies that utilize high standard processing equipment, which does not allow any defeat operations. It was a cooperation between EFT and one of the largest government organizations named Industrial Technology Research Institute. The objective was to develop the most suitable diaphragm material to achieve the process equipment requests from biopharmaceutical companies, which is exceedingly clean. As a result, when pharmaceutical companies realized that they can buy medicine processing equipment from EFT and get equivalent quality of products and services just like other well-known suppliers, EFT's business started to boom.

World-class forged stainless steel aseptic diaphragm valve

EFT's aseptic diaphragm valve is ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI (on the way) certified! EFT’s 3-A SSI aseptic diaphragm valve meets extreme needs of process cleanliness as in bio-pharmaceutical and food industries. Aseptic Diaphragm valves are tested for:

- minimum and maximum pressure,

- contamination test,

- material and welding factor,

- minimum tensile strength,

- leakage test of the valve body and seat,

- maximum design pressure or pressure class, and

- capacity for high temperature and acidity test.

World-class forged stainless steel diaphragm valve

Imported pharmaceutical / biotechnology component for your processing equipment

When you purchase processing equipment for your pharmaceutical production line, look no further than EFT. For an actuator diaphragm valve, the teflon is imported from Japan, and other important components are mostly imported from Germany and France. For example, the spring is an important component for actuator diaphragm valve, to assure their high tensile strength, they are imported with a report, which says it can undertake the usage of more than 2,000,000 times.

Stainless steel aseptic diaphragm valve for food processing equipment

EFT was invited to a yogurt company to visit their processing line due to their processing difficulties. The imperfect design of their diaphragm valve had ruined the production and they needed someone to find out what went wrong. Because the yogurt product line was using SIP system, when temperature went up, the rubber melted onto the screw and ripped the rubber. To solve the problem, EFT re-designed the valve by using a diaphragm to attach a screw - the diaphragm that was designed specifically for high temperature processing machines.

Class 10,000, ISO certified cleanroom for hygienic vacuum components

Cleanroom (class 10,000) For High Standard Diaphragm Valve: For semi-conductor, pharmaceutical, bio-technology and food processing industries, stainless steel diaphragm valves are required to be purified and particle-free. Therefore, EFT has set up a cleanroom that is equivalent to ISO standard. In the cleanroom, diaphragm valve components will be cleaned; the assembling and packaging processes will be done in the room before leaving the room.

10.Vacuum component and fitting supply

World standard vacuum component plant to meet your needs

EVERFIT TECHNOLOGY CO., LTD. (EFT) is a full service supplier dedicated to provide a wide range of stainless steel vacuum components, valves and product solutions for various fields including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering. EFT has a 5,500 square meter plant that is capable of performing mold design and manufacturing, heat treatment, casting, forging, plating, drilling, milling, CNC machining, cleaning, welding, assembling, and packing in a class 10,000 cleanroom. EFT is capable of delivering all stainless steel components comply with ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI criteria.

Stainless steel material report and test (SPECTRO iSORT):

Made in Taiwan high quality stainless steels with reports and tests

All of the stainless steel is procured from Taiwan's largest steel companies; they are Gloria Material Technology Corporation and Walsin Lihwa Corp. Even though made in Taiwan stainless steel is more expensive, its EFT’s determination ensures the steel quality. Besides material reports provided by the steel companies, when the steel arrives, it is tested using SPECTRO iSORT to assure its purity and that it is radiation-free. As soon as they are tested, they are tagged in various colors for identification.

Stainless steel vacuum component research and development (R&D) team:

EFT elites have been designing outstanding stainless steel valves and vacuum components that meet international standards

EFT has a team of six engineers with marvelous engineering experience in various industries including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering, and that's why they are capable of maintaining the partnership with international buyers from the U.S., France, Germany, Japan, U.K., Italy and Taiwan. EFT's stainless steel vacuum components are equivalent to world-class brands such as Alfa Laval, Gemü and SODIME because they follow their design concept and system. Low tolerance means 100% vacuum fitting test, and their good principle has allowed them to become a well-known manufacturer with high quality.

Mold design and development:

Excellent mold design and manufacturing skills is a factor for making stainless steel valves and vacuum fittings

For each stainless steel vacuum component, there are at least three molds designed and manufactured for the whole process, and the mold making cycle-time is driven in part by size and complexity. To reduce mold fabrication and development cycle time, years ago, instead of having their molds manufactured elsewhere, EFT started to design and fabricate their own molds. The mold design team utilizes the latest technology in hardware and software to design molds. With plenty of mold design experience, every mold has improved cycle times and eventually keeping the cost down.

Sawing machine:

Sawing machine for various types of stainless steel pipes and bars

In EFT, there are more than five 100% automatic sawing machines which are capable of working 24 hours non-stop. The high capability allows EFT to accept big orders and meet the deadlines. "One time they received an order for 500,000 stainless steel valves, the sawing machines were working 24 hours non-stop for days." The manager of EFT recalled.

High-frequency induction hardening machine for hot forging:

Stainless steel vacuum components and valves hot forging

High-frequency induction hardening machine is heating equipment for a wide range of industrial applications, especially for stainless steel vacuum pipes and bars. With the machine, the stainless steel vacuum pipes and bars are heated up to more than 1,000 degrees Celsius in a minute, once they are heated, they are shaped immediately by pressing machines.

Gas burner for hot forging:

Gas burner machine is heating equipment for flat stainless steel plates.

Pressing machine:

Vacuum fitting pressing process

For compressive forces, EFT has 200, 300 and 800 tons stamping pressing machines to handle a large quantity stainless steel vacuum equipment orders. The pressing machines are applied based on the stainless steel component’s weight range.

Upright type drilling machine:

Drilling machine for making stainless steel valves, vacuum fittings, vacuum components

EFT has ten drilling machines; they are capable of drilling stainless steel valves, vacuum fittings from 12mm diameter up to 42mm. Drilling machines are for hole drilling, after drilling, the drilled stainless steel vacuum fittings are moved to the CNC machining section for extra processing.

CNC lathe machine and milling machine for stainless steel vacuum valves, vacuum fittings:

In EFT's 5,500 square-meter plant, there are 18 CNC lathe machines, 2 CNC milling machines with 4 CNC lathe machine blade change engineers, which allowed EFT to manufacture stainless steel vacuum components from 3/8 to 8 diameters with 80,000 to 100,000's production capability per month.

CNC milling machines for vacuum components

Since every stainless steel vacuum fitting requires particular machining processes, for components that may need CNC machining or butterfly valves request milling, they are all arranged by the project manager based on their characteristics. All of the vacuum components can be requested for extra drilling, milling and cutting processes to meet the goals. Especially for high pressure stainless steel valves, which require high standard machining processes to achieve some challenging angles or axes.

Stainless steel vacuum component onsite inspection:

Onsite inspection with visual inspection, equipment inspection

During production, there's a card that goes along with the operator to make sure that every step is executed accurately, and the card indicates the tolerance of the stainless steel vacuum fittings, the temperature, and the number of times for rough surface grinding, etc. Supervisors are responsible to check the card and to measure stainless steel vacuum components every two hours regardless of the different stage of production. The stainless steel vacuum component is tested at the lab for its precision in order to prevent any defeat production.

Ultrasonic and RO Water cleaning process:

After CNC machining, each vacuum part has to go through a cleaning process to get rid of grease, dust, oil, etc. The whole process contains six sections including ultrasonic cleaning (container 1), ultrasonic cleaning (container 2), hot RO water cleaning (container 3), hot RO water cleaning (container 4), hot RO water cleaning (container 5) and dry (container 6).

Ultrasonic and RO water self-cleaning process for stainless steel vacuum components

RO water is one kind of purified water that removes molecules and ions using a high pressure technology. To avoid the unnecessary pollution from underground water, stainless steel vacuum components are cleaned using the most purified water - RO water.

To prevent friction during cleaning, there are custom-made racks to place each of the components separately.

Gauge and measuring tool for stainless steel vacuum components (valves, flange, stud clamp, pipe fitting):

There is testing equipment for individual stainless steel valves and vacuum fittings in EFT's testing lab and it is temperature controlled.

-

Crysta-Plus M 776:

- Crysta-Plus M 776 is easy-to-use coordinate measuring equipment that is used particularly for bolted flanges. The needle is able to hook up the hole and calculate its measurement accurately.

-

Mitutoyo contracer contour measuring instrument:

- The XY plotter contours the surface of stainless steel vacuum component and illustrates the distances and routes on the computer or other display units. It is suitable for measuring R and C angles.

-

Optical Comparator:

- Optical Comparator: Optical Comparator is an easy-to-use piece of equipment that can assist you to measure stainless steel vacuum fittings as soon as you place them on the platform. Readings are via .00005"/.001mm precision glass scales; it is suitable for measuring the thickness and oblique angle of components.

-

TECLOCK sylvac:

- TECLOCK sylvac can assist you to measure the depth of the vacuum components.

(From left to right)

Crysta-Plus M 776 (manual floating type coordinate measuring machine for stainless steel flange.)

Mitutoyo contracer contour measuring instrument.

Optical comparator for measuring.

TECLOCK sylvac.

Stainless steel vacuum component welding:

EFT custom made none-oxygen welding machine for prefect welded vacuum components

Custom-made welding machine is designed and built based on EFT’s years of experience. It is a none-oxygen welding machine, and its objective is to prevent oxygen porosity. With the newly designed welding machine, welding jobs are done perfectly.

Stainless steel vacuum component electroplating:

For some alloys that contain coppers, because of their characteristics, electroplating will be applied to prevent the change of colors.

Stainless steel vacuum component polishing:

After cleaning, each stainless steel vacuum fitting is polished and wiped just like a mirror.

Stainless steel vacuum component assembly:

vacuum component assembling

EFT is specialized in making stainless steel vacuum components for the semiconductor, food processing, and pharmaceuticals sectors. For some stainless steel vacuum components, they are assembled using more than 20 parts. Some parts are imported from Germany and Japan to present the best quality to their clients. For example, the German-made spring is tested for more than 200,000,0 times without breaking, and it comes with a report to prove it.

Stainless steel vacuum component testing:

Regardless of designing and manufacturing stainless steel vacuum components for semiconductor, food processing or pharmaceutical companies, precisely made components are required by them to ensure that the whole process is accurately done without accidents. Therefore, rigorous tests are conducted including water leak test, airless test, and sight glasses are applied for the tests as well.

Stainless steel vacuum component labeling:

Ink jet printing, laser printing, dot matrix printer or impact matrix printer are doable upon client's request.

Stainless steel vacuum component packaging and shipping methods:

Every client requires different packaging methods, EFT provides dynamic packaging ways to satisfy their needs. There is PE packaging, packaging, foam packaging, net packaging, or any other environmentally friendly packaging materials. In addition, before packing, visual inspection is performed to ensure the cleanness of each stainless steel vacuum component.

Cleanroom (class 10,000) for high standard stainless steel vacuum component:

Class 10,000, ISO certified cleanroom for hygienic vacuum components

For semi-conductor, pharmaceutical, bio-technology and food processing industries, stainless steel vacuum fittings are required to be purified and particle-free. Therefore, EFT has set up a cleanroom that is equivalent to ISO standard. In the cleanroom, stainless steel vacuum components will be cleaned; the assembling and packaging will be done in the room before leaving the room.

Stainless steel vacuum component inventory:

With a 5,500 square meter plant, EFT is capable of storing more than 200 tons of stainless steel materials to cope with large and urgent orders.

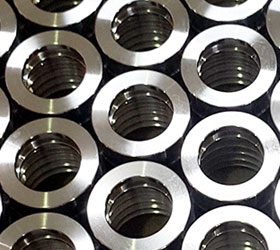

FERRULE QC inspection procedure

11.Stainless steel forged wine valves

French winemaker seeks manufacturing solutions in Taiwan: forged stainless steel wine valves

Many winemakers are requiring forged wine valves to replace the ones made using low pressure casting, to reduce contamination risk. For some companies that make 400,000 to 450,000 tons in a season, high wine quality is expected. In Taiwan, there’s a stainless steel vacuum component supplier who has taken one-step further and started using forging technology to make stainless steel wine valves. Today, Everfit Technology (EFT)'s forged wine valve is meeting zero defect production and allowing wine-making companies to produce fine wines.

One day, one of the leading wine valve and wine making equipment supply companies in France contacted EFT to consult with them about their wine valves. They used to buy low casting valves, however, the low quality valves brought many complaints and returns. They realized low casting might be cheaper at the beginning when comparing prices, but in the end it results in a great loss. Thus, an alternate solution is needed.

Knowing EFT has a forging factory, they flew to Taiwan for a visit. The client asked for a wine valve that would pass 3BAR pressure test. (actually valve pressure is tested up to 4BAR when conducting tests) EFT claimed that Double-sided welding would be performed to enforce strength, and that teflon and all other accessories are FDS certified.

To test the wine valve‘s pressure tolerance, EFT specifically designed a test equipment to test the valve, and purchased a world-renowned German-made pressure gauge to prove its accuracy. For every wine valve, there are three stages of leakage test to ensure high performance, and each process is strictly followed.

-

Stainless Steel Wine Valve Made From EFT:

- 20kg stainless steel is used for valve body.

- Precise positioning between parts - ball valve and valve body.

- Teflon is applied for tightness with great torsion.

- Double sided welding to assure shape quality.

- Anti - dust, anti-contamination.

- Self-developed leakage test equipment.

- Passed 4-BAR pressure test by the client.

- German world brand pressure gauge.

- Each stainless steel wine valve is 100% tested.

- One-stop stainless steel forging service.

![]() ”Companies always contact us after experiencing the results of the low casting process. Low pressure casting is cheaper but not after dealing with all the problems. The dilemmas usually include the low quality of valves; low casting supplier can’t meet the deadline, high cost for quality control and high defect rate. ” said Bert Huang, the vice president of EFT.

”Companies always contact us after experiencing the results of the low casting process. Low pressure casting is cheaper but not after dealing with all the problems. The dilemmas usually include the low quality of valves; low casting supplier can’t meet the deadline, high cost for quality control and high defect rate. ” said Bert Huang, the vice president of EFT.

"The biggest advantage to work with EFT is the access to our own forging factory. It allows EFT to provide one stop service from heat treatment, forging and finishing, and eventually to control the entire expense to lower the cost without sacrificing quality." said Tom Chang, the vice president of EFT.

Welding between two components

When conducting low pressure casting, defects occur for many reasons. For example, design part’s various thickness can cause different cooling time and therefore result in shrinkage and porosity. The low casting defects include blows, scars, blisters, scabs, misruns, cold shutting. hot tears, cracks, etc. When it happens, impregnation treatment is applied even though it’s not permitted in many industries.

Forging is a stronger, better response to heat treatment, high density, high quality with finishing work, and delivers a degree of structural integrity that is unique compared to other metalworking processes. Forging avoids the internal voids and gas pockets that can weaken metal parts. Stainless steel forging is suitable for semiconductors, food, pharmaceutical companies that ask for rigorous processing procedures.

As a result, every wine valve is state-of-the-art, tested and FDA certified. Currently EFT is working on this French company's 2nd order.

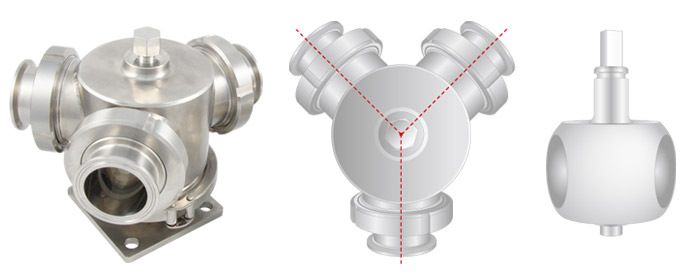

12.Multiport stainless steel valves from Taiwan

EFT multiport valve brings Japanese food & drink company 100% process security

In Japan, most multiport valves require only a 90-degree or 270-degree turn to operate the valve either completely open or closed, however, there are more and more companies designing stainless steel valves with various angles (ex: 135 degrees) to extend the valve market. Everfit Technology (EFT) is the only stainless steel forging company in Taiwan, and has been appointed as a priority supplier of many well-known companies.

There's a company in Japan that is specialized in designing, building and fixing all kinds of metal products. They wished to buy 135 degree steel valves. It is applicable for sampling, flow control, product transfer and reliably to provide process security. 100% leakage test, pressure test, onsite inspection and FDA certification were requested. Ease of maintenance, reasonable cost and desirable strength should meet their standards.

As the name implies, the ball valve uses a ball to stop or start the flow of fluid. It is difficult to position the ball in the center of valve body after switching filters. EFT’s 30 years of forging experience has allowed them to accumulate seasoned experience and known-how to come up with solutions. In the end, the Japanese engineer was thrilled by their technique.

During production, EFT had to modify the production procedure to prevent the change of the valve body’s shape. Welding was performed with correct thickness to achieve zero risk of contamination. The metalworking lathe machine is big enough and capable of doing the fine work.

ball valve washing

A 20kg stainless steel bar was forged down to a 3 way multi-port valve body. The 3 way multi-port valve has a complicated structure (135 degrees) that demands strong engineering knowledge. When making the sample production, EFT’s engineer made an inspection of gauges to avoid changing shape, a test equipment for pressure testing, and double sided welding to ensure its strength.

In the end, the marvelous stainless steel ball valve was appreciated by the Japanese company, and EFT is now 100% in charge of their ball valve production. (EFT started by making the ball at the beginning.)

"EFT's advantage is its ability to provide one-stop forging services, which allow us to bring the cost down at the same time still deliver high quality products. Many Japanese companies have been approaching us for their stainless steel valve manufacturing. We are not just an OEM supplier, we act as a consultant providing solutions to our clients, and their acceptance of our suggestions proves our value," said Bert Huang, the vice president of Everfit Technology.

Y type 3 way, 135 degrees ball valve, stainless steel ball on the right

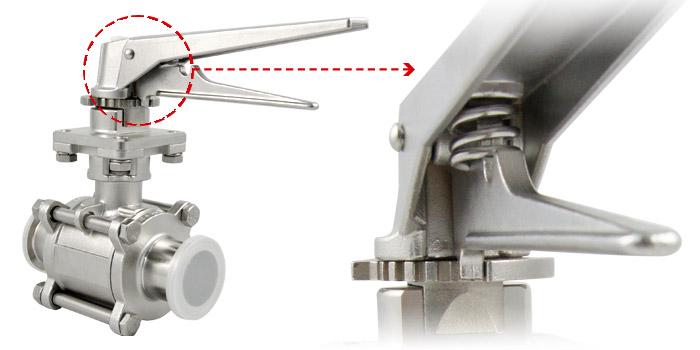

13.One-Stop forging service valve provider - EFT

EFT One-Stop forging service and state-of-The-Art technology serving worldwide companies

EFT obtains a multi-million dollar valve business from a leading Japanese semiconductor CMP slurry making company by achieving what other suppliers can't - one-stop forging service and state-of-the-art technology. Of course, FET’s achievement didn't happen in a day, it's the relentless pursuit of perfection.

Instead of welding, all pipes are attached with clamps to acquire easy-to-clean and fast installation purposes. EFT designs stainless steel butterfly valves that meet their client's demands - gripper handles, high standard electrolytic polishing, cleanroom assembling, etc.

For four days, the Japanese company visited EFT four times just to make sure they find the right supplier. They visited the factories, subcontractors, cleanrooms, test labs and material providers so they can have a full understanding of EFT.

For years, the company has been using the gripper handle for the valve due to its higher torsion and solid grip. However, most of the valve suppliers only provide lever handle. EFT sustains the gripper handle and designs the handle with lower cost, which is one of the issues they would like to solve.

Ball valve with a gripper handle and 6 opening positions

Class 10,000 clean room assembling is conducted at EFT to ensure the client's valve quality. Each pipe is attached by a clamp instead of welding to achieve easy-to-clean and fast installation purposes.

High quality electropolishing is one of the requests from the company. Yet, stainless steel electropolishing means high friction and can result in high torsion. Fortunately, EFT’s know-how assisted them to carry out both advantages - high torsion and no valve leakage.

At the beginning, the Japanese company asked EFT to make only the stainless steel balls just to test out their reliability, now EFT is taking charge of whole butterfly valves' production. So far, there are not that many suppliers who are capable of reaching the company's requirements, and that's why EFT is able to win the contract above others.

Everfit Technology CO., LTD. (EFT) is a forging service provider who’s been providing stainless steel valves for companies that require high quality manufacturing processes. High performance processing standards means no valve leakage and low risk of contamination in various industries, particularly in pharmaceutical, food and drink and semiconductor industries.

"EFT has a large inventory! We provide designs and tests to meet your requirements in a short time with reasonable prices.", said Bert Huang, the vice president of Everfit Technology.

14.EVERFIT TECHNOLOGY CO., LTD. (EFT)

Excellent vacuum component design engineering. Manufacturing. Precise testing from a taiwan supplier - EFT

In 2011, Everfit Technology CO., LTD. (EFT) has expanded their current plant to broaden their services in OEM and ODM stainless steel vacuum components for various industries including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering.

It is a 5,500 square meter plant that is capable of performing mold design and manufacturing, heat treatment, casting, forging, plating, drilling, milling, CNC machining, cleaning, welding, assembling, and packing. The enlarged plant with two production lines not only shortens the lead-time, the additional equipment, welding machine and cleanroom (class 10,000), also allows EFT to deliver quality stainless steel vacuum fittings with high-end technologies. Overall, all of the jobs are done based on a functional system and a team of elites with 36 years of seasoned experience.

Everfit Technology CO., LTD. (EFT) History

| Year | Issue |

|---|---|

| 2011 | EFT 5,500 square meter plant created |

| 2011 | EFT received TAF ISO certification |

| 2011, Feb. | EFT developed aseptic stainless diaphragm valve technology and applied 3-A SSI |

| 2007 | EFT's electroless nickel pipes sold to Japan |

| 2006 | EFT developed vacuum components for semiconductor industry |

| 2006 | EFT developed BPE level bio-technology vacuum valves to England |

| 2006 | EFT implanted a forging sector and two product lines |

| 2003 | EFT was TSSA CRN certified |

| 2002 | EFT obtained ISO 9001 DNV |

| 1976 | EFT established |

EFT works with quality suppliers to provide world-class vacuum components and stainless steel valves.

Walsin Lihwa Corp. is a leading manufacturer of bare copper wire, wire and cable, and specialty steel in the Greater China region, and has also successfully expanded into the high-tech industry and become an international enterprise with green energy, photovoltaics, real estate, and trade operations.

Gloria Material Technology Corporation (GMTC) is the first specialty steel manufacturer in Taiwan to engage in the manufacture of special alloy materials.

Sanyo Special Steel Co., Ltd. is the only domestic manufacturer specializing in special steel that has tube plants, manufacturing bearing steel, engineering steel, and stainless steel, as well as super alloy tubes and other seamless steel tubes/pipes.

POSCO became the top of the world steel industry in 1998. The year 1999 was witness to a total revamping of the Company's overall processes in procurement, production, and sales, and the construction of an integrated digital system.

Yeun Chyang Industrial Co., Ltd. is the biggest service center for stainless steel. Their products are: stainless steel coil, stainless steel sheet, stainless steel plate, stainless steel welded pipe, stainless steel welded tube, stainless steel angles, stainless steel flat bar, and stainless steel U channel

FROCH ENTERPRISE (FROCH) is established in 1984, FROCH has been working relentlessly in making quality stainless steel pipes, tubes, sheets, and coils, and is a specialized manufacturer for stainless steel tube and pipe.

The vast selection of stainless steel valves and vacuum components for your control systems:

- Stainless Steel Seat Valves

- Diaphragm Valves (or membrane valves)

- Tank Valves

- Butterfly Valve Actuators

- Butterfly Valves

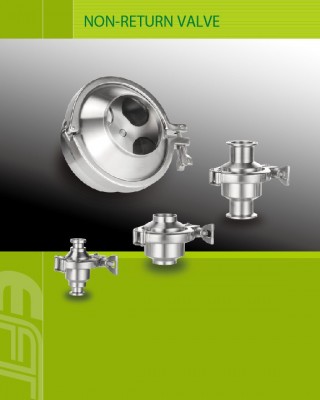

- Non Return Valves

- Sight Glasses (sight flow indicator)

- Sample Cock Valves

- Safety and Relief Valves

- Filling Valves

- Ball Valves

- Clamp/ Ferrule

- Union

- Stainless Steel Pipe Clamps / Stainless Steel Pipe Ferrules

- Stainless Steel Pipe Ferrule Adapters

- Stainless Steel Union Parts

- Stainless Steel Pipe Fittings( ASME BPE)

- Stainless Steel Sanitary Tubes (TEE, Reducer, Cross, Bend)

-

Vacuum Component and Fitting Test Equipment:

- SPECTRO iSORT

- Crysta-Plus M 776

- Mitutoyo Contracer Contour Measuring Instrument

- Optical Comparator:Optical Comparator

- TECLOCK sylvac

EFT stainless steel vacuum component and valve production lines and engineers

EFT obtained ISO 9001 and TSSA CRN to prove their vacuum component's technical and safety standard

15.Contact a vacuum component and valve supplier for processing equipment solutions

Contact now to get professional design solutions!

Everfit Technology CO., LTD. (EFT) is a stainless steel vacuum components, vacuum fittings, valves and processing equipment provider with 35 years of experience; their stainless steel processing equipment is applied in dynamic areas containing semi-conductors, pharmaceuticals, bio-technology, food processing and structural engineering to provide process controls for solid and fluid materials. They assure stable control processes and cost effective production flows in all important aspects.

16.Send inquiry to a Taiwan vacuum component supplier

Send a vacuum fitting inquiry now –

EFT respond with 24 hours

Everfit Technology CO., LTD. (EFT) is a stainless steel vacuum components, vacuum fittings, valves and processing equipment provider with 35 years of experience; their stainless steel processing equipment is applied in dynamic areas containing semi-conductors, pharmaceuticals, bio-technology, food processing and structural engineering to provide process controls for solid and fluid materials. They assure stable control processes and cost effective production flows in all important aspects.

17.EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

Ready-Online.com websites (collectively “Ready-Online.com“) refer to sites hosted on the Ready-Online.com domains and subdomains thereof. Ready-Online.com website provides a platform for EVERFIT TECHNOLOGY CO., LTD. (EFT) to showcase their stories and products in order to attract visitors with product inquiries. When visitors send inquiries, information obtained in connection with the site may be used by EVERFIT TECHNOLOGY CO., LTD. (EFT). Ready-Online.com regularly collects and processes information about visitors who use the website and inquiry form which we operate and control, and for which we may be deemed to act as the Data Controller.

Personal Information You Provide to Us through Our Site.

Certain visitors choose to interact with Ready-Online.com in ways that require Ready-Online.com to gather personally-identifying information. The amount and type of information that Ready-Online.com gathers depends on the nature of the interaction. We collect, process and use your personal data for specific purposes if you have given your consent to the collection, processing and use of specific personal data for such purposes. You may withdraw your consent any time.

The types of personal information may include:

Company name, contact name, job title, company website, country, business type, email, telephone number, fax number, address.

Cookie: