One-Stop forging service valve provider - EFT

Class 10,000 clean room assembling. Gripper handles.

High standard electrolytic polishing

EFT One-Stop forging service and state-of-The-Art technology serving worldwide companies

EFT obtains a multi-million dollar valve business from a leading Japanese semiconductor CMP slurry making company by achieving what other suppliers can't - one-stop forging service and state-of-the-art technology. Of course, FET’s achievement didn't happen in a day, it's the relentless pursuit of perfection.

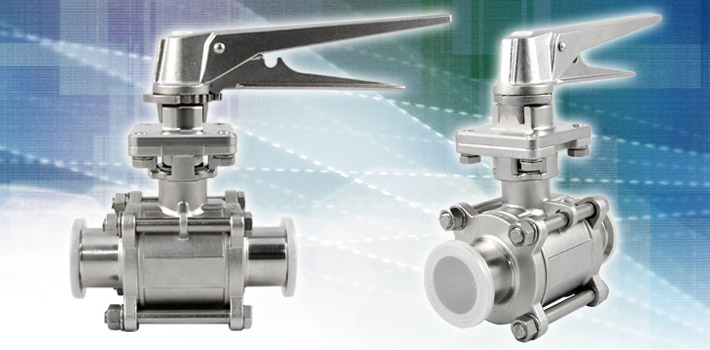

Instead of welding, all pipes are attached with clamps to acquire easy-to-clean and fast installation purposes. EFT designs stainless steel butterfly valves that meet their client's demands - gripper handles, high standard electrolytic polishing, cleanroom assembling, etc.

For four days, the Japanese company visited EFT four times just to make sure they find the right supplier. They visited the factories, subcontractors, cleanrooms, test labs and material providers so they can have a full understanding of EFT.

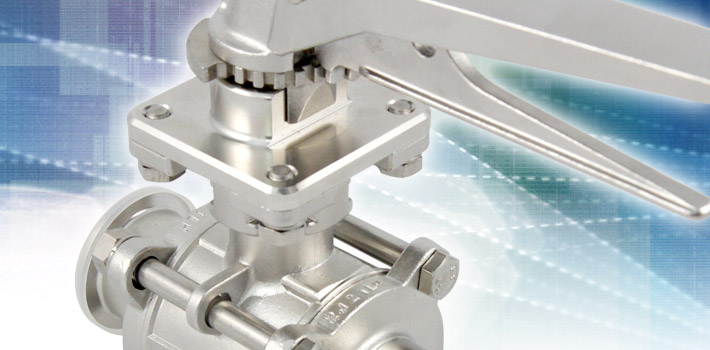

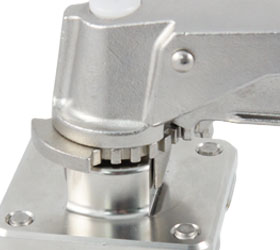

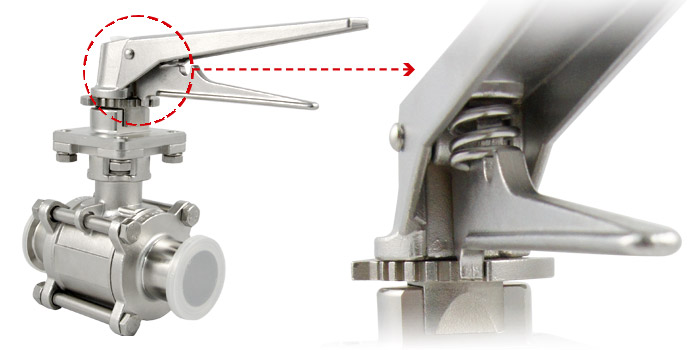

For years, the company has been using the gripper handle for the valve due to its higher torsion and solid grip. However, most of the valve suppliers only provide lever handle. EFT sustains the gripper handle and designs the handle with lower cost, which is one of the issues they would like to solve.

Ball valve with a gripper handle and 6 opening positions

Class 10,000 clean room assembling is conducted at EFT to ensure the client's valve quality. Each pipe is attached by a clamp instead of welding to achieve easy-to-clean and fast installation purposes.

High quality electropolishing is one of the requests from the company. Yet, stainless steel electropolishing means high friction and can result in high torsion. Fortunately, EFT’s know-how assisted them to carry out both advantages - high torsion and no valve leakage.

At the beginning, the Japanese company asked EFT to make only the stainless steel balls just to test out their reliability, now EFT is taking charge of whole butterfly valves' production. So far, there are not that many suppliers who are capable of reaching the company's requirements, and that's why EFT is able to win the contract above others.

Everfit Technology CO., LTD. (EFT) is a forging service provider who’s been providing stainless steel valves for companies that require high quality manufacturing processes. High performance processing standards means no valve leakage and low risk of contamination in various industries, particularly in pharmaceutical, food and drink and semiconductor industries.

"EFT has a large inventory! We provide designs and tests to meet your requirements in a short time with reasonable prices.", said Bert Huang, the vice president of Everfit Technology.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products