Pharmaceutical sampling valves supply

EFT success story – excellent sampling valve machining job for U.S. client

SIP/CIP stainless steel processing equipment

Strong sample valve component machining skills winning U.S. client's heart

In Taiwan, the most complicated sampling valve component machining service was conducted by EFT; their state-of-the-art sampling valve components helped convince a U.S. process equipment supplier to double their orders and increase payment. Due to the sampling valve component business opportunity, EFT not only took a big step on enforcing their machining skills, they also expanded their market in the pharmaceutical industry worldwide.

Difficult Machining Jobs for Pharmaceutical Sampling Valves

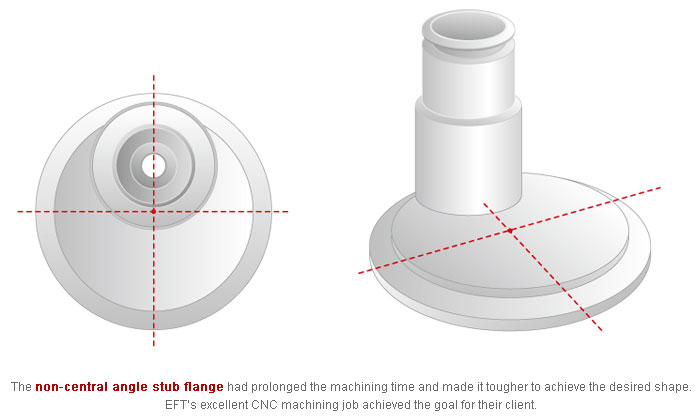

When FET received the sampling valve component inquiry, they realized it wasn't an easy job. It was a component for vaccine processing equipment that requires specific CNC and milling machining processes due to its specific design. It has a stainless steel flange with a stub welded near the central point. However, the non-central angle stub flange had prolonged the machining time and made it tougher to achieve the desired shape. It was time-consuming and difficult! It took hours to complete one, which made the cost of production go way up. Nevertheless, when the U.S. company's engineer saw the work, they were thrilled. After the first shipment, EFT received a new procurement for double the amount of sampling valve components, and the U.S. company was willing to pay more for the high performance. EFT engineers have been finding solutions to cut down the product costs.

Forged stainless steel sampling valve component

While some valve suppliers are still using sand casting or other casting methods to fabricate sampling valves, EFT had already started using stainless steel to forge the components for their solidness and product qualities. When manufacturing a sampling valve for a vaccine production facility; every pharmaceutical company requires a precise sampling valve to avoid leaking or contamination accidents, only stainless steel forging can create the densest one. EFT purchases their stainless steel directly from steel companies in Taiwan to ensure their 100% purity.

![]() The U.S. company is a manufacturer of hygienic and extreme clean stainless steel components for use in the biotechnology and pharmaceutical industries. Their stainless steel products including processing equipment for fluid line heat exchangers, sample coolers, SIP-ABLE sample valves, angle bleed and sample valves, inline bleed and sample valves, tee block bleed and sample valves, thermowells, stability test valves, co-axial tube, dip tubes, instrument tees & CPM's, custom and standard filter housings.

The U.S. company is a manufacturer of hygienic and extreme clean stainless steel components for use in the biotechnology and pharmaceutical industries. Their stainless steel products including processing equipment for fluid line heat exchangers, sample coolers, SIP-ABLE sample valves, angle bleed and sample valves, inline bleed and sample valves, tee block bleed and sample valves, thermowells, stability test valves, co-axial tube, dip tubes, instrument tees & CPM's, custom and standard filter housings.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products