Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

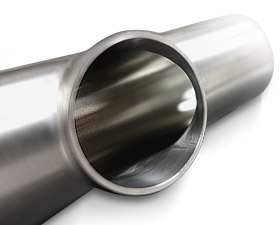

±0.02mm uniform wall-thickness, robotic welding, ASTM A270-S2

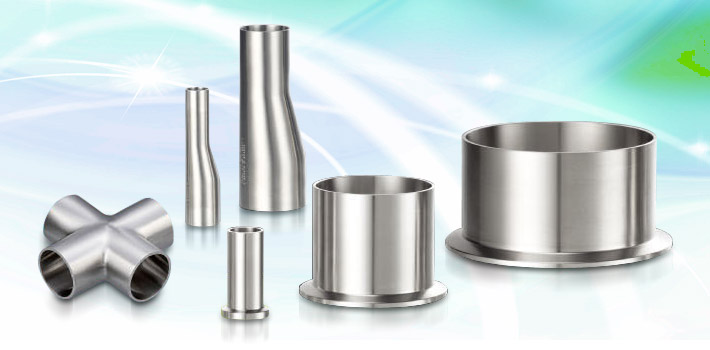

High quality vacuum pipe fitting for semiconductor and biopharmaceutical industry

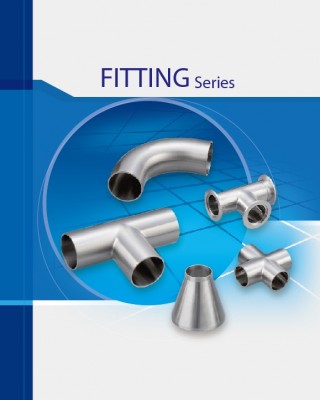

Pipe tee supply - 20 times cheaper with sophisticated pulling technology

Sanitary tee with perfect circle using pull technology

Because of Everfit Technology CO., LTD. (EFT)’s pipe tee pulling technology, making an impeccable sanitary tee that is made of tube 316, with low sulfur content, manufactured to stringent ASTM A270-S2 specifications with lowered cost is possible. As a result, a world leading vacuum pipe fitting company from Israel made an expanded procurement with Everfit Technology to enhance their cooperative relationship.

The client was a worldwide leader in the manufacturing of process stainless steel fittings for biopharmaceuticals and semiconductors; and a leading manufacturer of sanitary valve & actuators for food and cosmetics industries. Their requirements were strict.

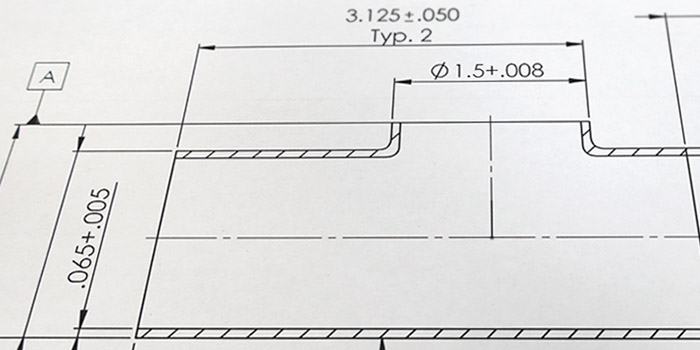

Specification requirements of T-shaped pipe tee from client with strict standards

Pipe Tee's Manufacturing Plan to Achieve 100% Perfection

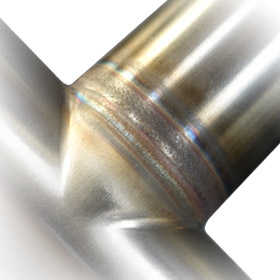

Robotics welding on T-shaped pipe tee to increase its accuracy, repeat-ability, and throughput

Everfit Technology’s engineering team delivered a plan regarding a pipe tee's circularity, pulling percentage, mold design and welding method after receiving an inquiry. Robotic welding is applied to assure the fluid in the stainless steel fitting flows smoothly. Moreover, pipe’s pulling percentage is calculated to achieve correct thickness and roundness, and the mold should be able to clamp precisely to assure its pulling performance.

Pipe-Pulling stainless steel tee – reasonable priced and beautifully made

Rather than using hydraulic tee forming technology, which is expensive because of the cost of forming machine and mold-making, Everfit Technology decided to use the pipe-pulling method, which also includes mold-making and robotic laser welding. Pipe pulling technology is relatively hard to do; elegant mold design and pipe pulling operation experience and skills are required. If it fails, buckling and splitting could occur.

Pipe-pulling requires technology that depends on the configuration of the mold, the pull force, and the pipe condition; it took rigorous trials to make it work.

helium leak test

-

The Israeli client asked for 20 sample products. Each t-shaped tee had to be:

- Tube 316L with low sulfur content (0.005-0.017%). In accordance with ASTM A270-S2.

- Longitudinal and circumferential scratches are not allowed.

- Welding type:tig/laser/robotic welding

- The wall thickness across the seam should not deviate more than ±0.02 mm with respect to the nominal wall-thickness of the tube.

- The seam should be uniform, having "full penetration" with no "under-cut", "protrusions", etc.

- The seam should be free of "oxidation" and "porosity", with no evidence of "lack of fusion", or "incomplete fusion".

- The seam should be "internally bead rolled" in order to have a uniform wall-thickness across the weld area.

Stainless steel pipe fitting that is 20 times cheaper

Normally, the only method to build high-quality sanitary tee is to use one-step forming technology. The process makes perfect stainless steel tees; however, it is very costly. The equipment and mold making could cost millions, let alone one mold can only produce tee pipes with one size.

Everfit Technology's piping and plumbing fittings were able to meet the Israeli client's needs for the pharmaceutical industry. Everfit Technology’s T-shaped pipe tee meets roundness tolerance, and both outlets are 90 degrees connected to the main line. The penetration welding was conducted by a robot that leaves a smooth surface and met ASTM standards.

It was challenging, but Everfit Technology was ready. Years of serving international clients has allowed them to have the flexibility to come up with strategic solutions, such as mold and gauge design, in order to achieve requirements of the customer.

T-shaped pipe tee

Everfit Technology CO., LTD. – A professional stainless steel welding tee supplier from Taiwan

vacuum component precise welding

Sometimes, it is all about the timing; the requirement came while Everfit Technology was working on bathroom faucet's development; therefore, everything was ready.

Combining years of vacuum component experience, existing equipment, matured mold and gauge design technology, Everfit Technology was able to make pipe fittings meeting the client's rigorous standards. And the most important thing was that the cost of pipe tee was lowered. The manufacturing of stainless steel sanitary fittings not only allowed Everfit Technology to open up a new market, but it is also cost-saving without sourcing elsewhere.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products