Multiport stainless steel valves from Taiwan

90, 135, 270-Degree forged valves for food & drink industry

Solid. No leakage. Pressure tested. Certified

EFT multiport valve brings Japanese food & drink company 100% process security

In Japan, most multiport valves require only a 90-degree or 270-degree turn to operate the valve either completely open or closed, however, there are more and more companies designing stainless steel valves with various angles (ex: 135 degrees) to extend the valve market. Everfit Technology (EFT) is the only stainless steel forging company in Taiwan, and has been appointed as a priority supplier of many well-known companies.

There's a company in Japan that is specialized in designing, building and fixing all kinds of metal products. They wished to buy 135 degree steel valves. It is applicable for sampling, flow control, product transfer and reliably to provide process security. 100% leakage test, pressure test, onsite inspection and FDA certification were requested. Ease of maintenance, reasonable cost and desirable strength should meet their standards.

As the name implies, the ball valve uses a ball to stop or start the flow of fluid. It is difficult to position the ball in the center of valve body after switching filters. EFT’s 30 years of forging experience has allowed them to accumulate seasoned experience and known-how to come up with solutions. In the end, the Japanese engineer was thrilled by their technique.

During production, EFT had to modify the production procedure to prevent the change of the valve body’s shape. Welding was performed with correct thickness to achieve zero risk of contamination. The metalworking lathe machine is big enough and capable of doing the fine work.

ball valve washing

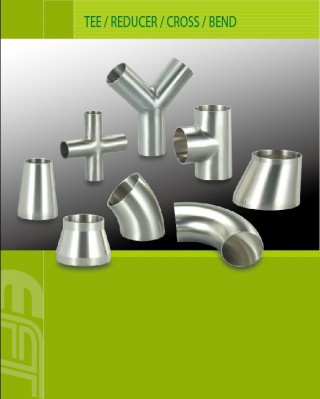

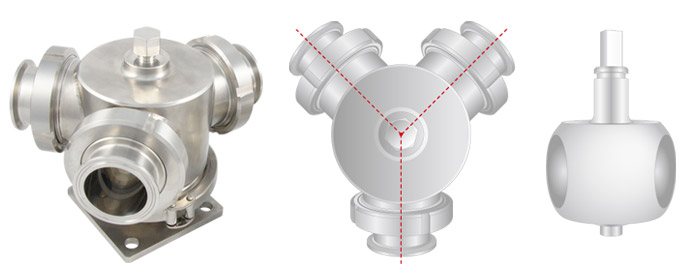

A 20kg stainless steel bar was forged down to a 3 way multi-port valve body. The 3 way multi-port valve has a complicated structure (135 degrees) that demands strong engineering knowledge. When making the sample production, EFT’s engineer made an inspection of gauges to avoid changing shape, a test equipment for pressure testing, and double sided welding to ensure its strength.

In the end, the marvelous stainless steel ball valve was appreciated by the Japanese company, and EFT is now 100% in charge of their ball valve production. (EFT started by making the ball at the beginning.)

"EFT's advantage is its ability to provide one-stop forging services, which allow us to bring the cost down at the same time still deliver high quality products. Many Japanese companies have been approaching us for their stainless steel valve manufacturing. We are not just an OEM supplier, we act as a consultant providing solutions to our clients, and their acceptance of our suggestions proves our value," said Bert Huang, the vice president of Everfit Technology.

Y type 3 way, 135 degrees ball valve, stainless steel ball on the right

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

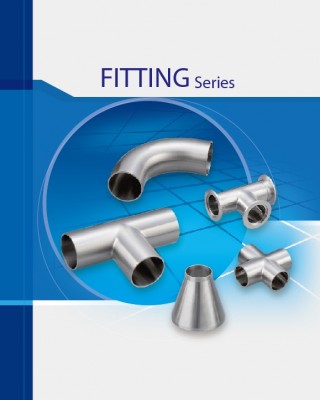

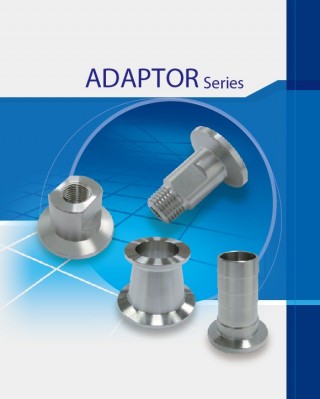

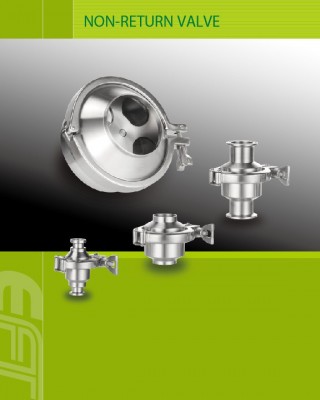

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products