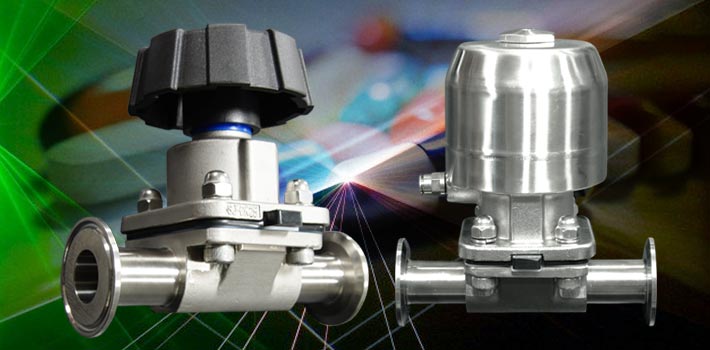

ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

SIP/CIP system aseptic diaphragm valve

Diaphragm valve for food processing. pharmaceutical, biotechnology

Medicine processing equipment tested by famous pharmaceutical companies in England, Germany and Japan

EVERFIT TECHNOLOGY CO., LTD. (EFT) sanitary diaphragm valves were tested at the pharmaceutical companies, and the companies were applying cleaning-in-place (CIP) and sterilization-in-place (SIP) self cleaning and sanitation systems in England, Germany and Japan. They are world leading pharmaceutical companies that utilize high standard processing equipment, which does not allow any defeat operations. It was a cooperation between EFT and one of the largest government organizations named Industrial Technology Research Institute. The objective was to develop the most suitable diaphragm material to achieve the process equipment requests from biopharmaceutical companies, which is exceedingly clean. As a result, when pharmaceutical companies realized that they can buy medicine processing equipment from EFT and get equivalent quality of products and services just like other well-known suppliers, EFT's business started to boom.

World-class forged stainless steel aseptic diaphragm valve

EFT's aseptic diaphragm valve is ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI (on the way) certified! EFT’s 3-A SSI aseptic diaphragm valve meets extreme needs of process cleanliness as in bio-pharmaceutical and food industries. Aseptic Diaphragm valves are tested for:

- minimum and maximum pressure,

- contamination test,

- material and welding factor,

- minimum tensile strength,

- leakage test of the valve body and seat,

- maximum design pressure or pressure class, and

- capacity for high temperature and acidity test.

World-class forged stainless steel diaphragm valve

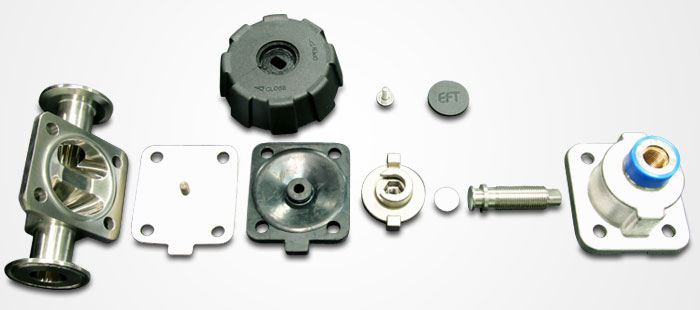

Imported pharmaceutical / biotechnology component for your processing equipment

When you purchase processing equipment for your pharmaceutical production line, look no further than EFT. For an actuator diaphragm valve, the teflon is imported from Japan, and other important components are mostly imported from Germany and France. For example, the spring is an important component for actuator diaphragm valve, to assure their high tensile strength, they are imported with a report, which says it can undertake the usage of more than 2,000,000 times.

Stainless steel aseptic diaphragm valve for food processing equipment

EFT was invited to a yogurt company to visit their processing line due to their processing difficulties. The imperfect design of their diaphragm valve had ruined the production and they needed someone to find out what went wrong. Because the yogurt product line was using SIP system, when temperature went up, the rubber melted onto the screw and ripped the rubber. To solve the problem, EFT re-designed the valve by using a diaphragm to attach a screw - the diaphragm that was designed specifically for high temperature processing machines.

Class 10,000, ISO certified cleanroom for hygienic vacuum components

Cleanroom (class 10,000) For High Standard Diaphragm Valve: For semi-conductor, pharmaceutical, bio-technology and food processing industries, stainless steel diaphragm valves are required to be purified and particle-free. Therefore, EFT has set up a cleanroom that is equivalent to ISO standard. In the cleanroom, diaphragm valve components will be cleaned; the assembling and packaging processes will be done in the room before leaving the room.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

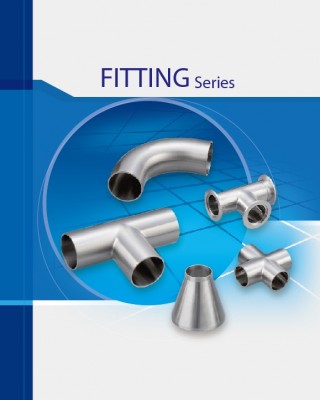

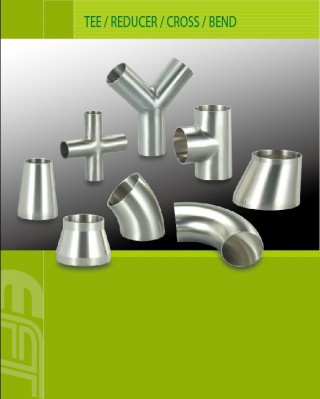

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

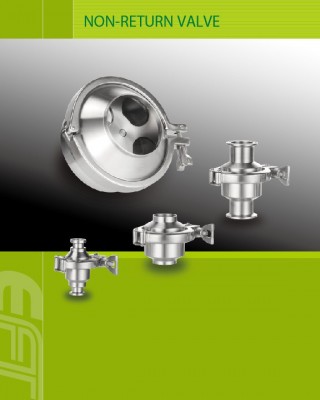

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products