EVERFIT TECHNOLOGY CO., LTD.

One of leading stainless Steel Pipe Fittings Manufacturers for Your Industrial Vacuum Pumps

Everfit Technology CO., LTD. (EFT) is one of the stainless steel pipe fittings manufacturers based in Taiwan with over 36 years of experience. EFT provides 316, 316Ti stainless steel pipe fittings, pipe reducer, eccentric pipe reducer, vacuum pump, valve actuator - ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI certified.

1.Ferrule and vacuum component supplier for processing equipment solutions

Clamp Style Fittings are most popular for easy assembly and breakdown of process lines and equipment. EFT offers Clamp Fittings in 316L materials in 1.5˝ through 8˝ sizes.

Gaskets for Clamp Fittings are available in several different materials, EPDM, Silicone, Vition®, and Viton®. Lightweight and heavy-duty clamps complete the unions. EFT’s Clamp Fittings meet all 3A requirements.

2.KF Flange Series and vacuum component supplier for processing equipment solutions

The Small flange or KF standard (DIN 28403, ISO 2961) is the standard connection for vacuum pipes up to the nominal diameter of DN50 used in low, fine and high vacuum.

A seal is positioned between the flanges. The seal consists of a centering ring and the O-ring stretched upon. The flanges are held together by a clamp. The clamp has an inclined interior surface adequate to the conical outer surface of the flanges.

Usually centering rings and standard clamps are used with wing nuts. They enable a quick and easy assembly without any tools. Trapped centering rings and special clamps or clamp chains are offered for special applications.

Claw clamps or so-called bulkhead clamps are available for wall mounting.

3.ISO Flange Series and vacuum component supplier for processing equipment solutions

ISO KF vacuum systems employ components with metric interface dimensions which have been defined by the International Standards Organisation (ISO).This ensures a high degree of compatibility between components obtained from different sources.

EFT Vacuum ISO KF are compatible with Klein Flange (KF) types. Use ISO KF for tube sizes DN16 to DN50. Our standard range of KF flanges and fittings are manufactured from 304 (1.4301) stainless steel.

Maximum temperature for sustained use is 150°C. They are ideal for vacuum systems requiring regular assembly and disassembly. Each vacuum seal is made by compression of an O-ring on a centring ring between mating flanges. The seal is made in seconds

by finger-closure of a wing nut on the all-metal hinged aluminium clamp.

The ISO KF family of modular building block components includes all commonly used standard fittings, feedthroughs and accessories. Reducing flanges are available to connect different size components.

Mating flanges are offered to interface with pipe and other flange systems including LF and CF.

4.CF Flange Series and vacuum component supplier for processing equipment solutions

The generation of ultra high vacuum (UHV) makes great demands on the material and connections. Therefore the CF standard was created in the UHV technology (ISO 3669; enhancement ISO/TS 3669-2).

CF flanges are manufactured from circular blanks of stainless steel on CNC machines. Rotatable flanges are bipartite and consist of an inner part with the seal face and an outer part with the bolt holes.

CF flanges have an annular groove on the vacuum side for the reception of the gasket and a knife-edge.

EFT provides CF flanges and components of the dimensions DN10 to DN250 according to the pre-norm ISO/TS 3669-2. Please consider that individual standards of institutions are also available in the market. Please add the auxiliary dimensions

(DN25, DN50, DN75, DN125) in case of requests and offers of CF flanges and components. In addition please add the size and the number of required bolts and the necessary copper gasket for dimensions from DN250.

EFT follows the widely used convention of categorising different sizes of UHV flange by using a ‘DN’ specification.‘DN’ is the acronym of the French term ‘Diamètre nominal’ which translates as ‘Nominal bore’. The bore referred to is that of the tube that fits inside the designated flange. The bore is ‘nominal’because of the variation in tube wall thickness.

5.Bellow Series and vacuum component supplier for processing equipment solutions

EFT 304 (1.4301) stainless steel tube is suitable for all high and ultrahigh vacuum applications. The material is priced per metre.

EFT is pleased to showcase this range of edge-welded bellows connectors for UHV.

These allow lateral movement, off-axis movement and vibration isolation.

Offered with four standard fittings Weldable CF or ISO KF and LF flanges, our bellows are manufactured to the highest standards of cleanliness for UHV applications. All bellows are constructed from stainless steel grade AM350 with connectors in SS304 material.

Special bellows assemblies and custom fabrications are also available on request.

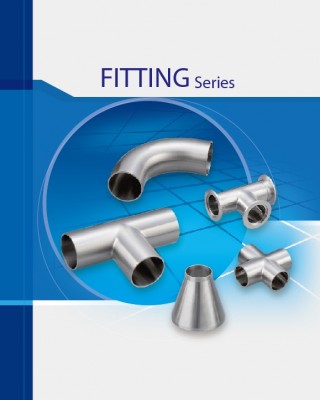

6.Fitting Series and vacuum component supplier for processing equipment solutions

EFT's ISO KF and ISO LF tube fittings are convenient building-block components. They offer great flexibility in the design and construction of high vacuum systems. All fittings are fabricated from 304 stainless steel drawn and welded vacuum tubing. Flanges do not need to be rotatable since they are completely symmetric. If desired, rotatable bolt ring assemblies can be retrofitted to existing claw-clamp style flanges to add bolt holes to ISO LF fittings. Reducers are used for a change in size of flanges within a single method of sealing, such as elastomer sealing of ISO KF and LF flanges

Custom configurations available on request

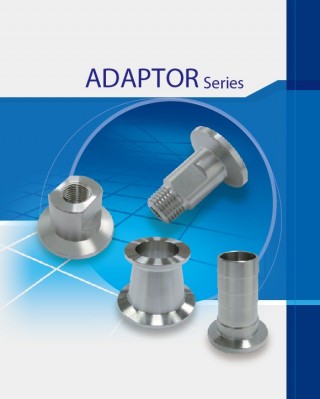

7.Adaptor Series and vacuum component supplier for processing equipment solutions

EFT hybrid adaptors provide a transition from one method of sealing to another. The hybrid feature of these adaptors is that the geometries at each end of any component are different.

This is more than a change in size within a particular sealing method.

They are available in most of the common interface transition pairs.

There are two major categories of adaptors: one combines pairs of standard vacuum flanges and the other combines standard fittings with flanges.

A frequent transition is from a metal seal flange to an O-ring sealed flange or fitting. Specifications are generally limited by the introduction of an O-ring seal. include at least one nonmetal seal and are therefore limited to high vacuum applications.

Refer to individual component sections for specifications. Reducers are a change in size within a particular flange sealing method, such as metal-seal to metal-seal. Reducers within a specific sealing method can be found in the fittings portion of each flange section.

Custom configurations available on request

8.Diaphragm Valve and vacuum component supplier for processing equipment solutions

EFT has developed a line of valve bodies that help address the needs of the Bioprocessing and Pharmaceutical industries for high quality, welded process systems.

By providing valve bodies with controlled sulfur SS316L stainless steel material and weld tangents long enough to accept the most common orbital weld heads in the industry, we have eliminated two of the most common concerns in valve-to-tube welding known today.

Automatic welding of 316L process components is greatly affected by the sulfur content of the mating process components. A disparity of sulfur content can result in reduced orbital weld quality and potentially incomplete fusion of the mating components. By controlling valve body sulfur content to the same chemistry as that required for ASME BPE fittings, welding problems due to material chemistry differences will be greatly reduced.

The EFT of valve bodies fully complies with the controlled sulfur requirements for chemical composition of SS316L material, set by the ASME Bioprocessing Equipment Standard 2002. By increasing the valve weld end tangent lengths to the values required for ASME BPE fittings, we made the valve body compatible with virtually any orbital weld head utilized in the industry. Special offset or narrow heads are no longer required to weld a valve into a process system.

9.The Original Seat Valve and vacuum component supplier for processing equipment solutions

Ideal for uninterrupted production in a broad range of hygiene-critical applications, Unique single seat valves are pneumatic seat valves used to shut off or change product flow.

EFT Seat valves are the extremely reliable all-rounders in the valve world. Our range includes on/off and control valves in stainless steel, with a stainless steel bonnet or a lightweight plastic actuator. They are available with a threaded or Tri-clamp connection, actuation is either pneumatically or motor-driven and they can be supplied with a flanged body. EFT Seat valves has very flexible design which meets sanitary requirements, and is mainly used in pipeline systems without contaminant or mixture. As a modern and widely-used valve, it is mainly used in the wine brewing, dairy, beverage, and pharmaceutical industries.

EFT Seat valves is remotely operated by means of compressed air. By controlling the relative position of valve plug, it makes the valve open or closed, or changes the flow direction of media. EFT Seat valves is equipped with our smart controller, which not only remote controls the single-seat valve, but can also perform real-time monitoring of the valve working conditions and timely feedback of signals. It can also be equipped with the position sensor only.

10.The Original Manual Seat Valve and vacuum component supplier for processing equipment solutions

Ideal for uninterrupted production in a broad range of hygiene-critical applications, Unique single seat valves are pneumatic seat valves used to shut off or change product flow.

EFT Seat valves are the extremely reliable all-rounders in the valve world. Our range includes on/off and control valves in stainless steel, with a stainless steel bonnet or a lightweight plastic actuator. They are available with a threaded or Tri-clamp connection, actuation is either pneumatically or motor-driven and they can be supplied with a flanged body. EFT Seat valves has very flexible design which meets sanitary requirements, and is mainly used in pipeline systems without contaminant or mixture. As a modern and widely-used valve, it is mainly used in the wine brewing, dairy, beverage, and pharmaceutical industries.

EFT Seat valves is remotely operated by means of compressed air. By controlling the relative position of valve plug, it makes the valve open or closed, or changes the flow direction of media. EFT Seat valves is equipped with our smart controller, which not only remote controls the single-seat valve, but can also perform real-time monitoring of the valve working conditions and timely feedback of signals. It can also be equipped with the position sensor only.

11.The Original Manual Tank Valve and vacuum component supplier for processing equipment solutions

EFT is a pneumatic seat valve with sanitary and flexible design. Based on the mature single seat valve design platform, few and simple moving components make the valve reliable, and reduce the maintenance cost. FS3 tank bottom valve is used to close or open the pipe leading to the tank. It is widely used in brewing, dairy, beverage, and pharmaceutical industries.

EFT tank bottom valve is remote controlled by compressed air, which consists of one valve and one tank bottom flange. In order to reduce the abrasion of seal components, the compression to seal components is performed through touching between metals.

The modular design of the valve in connection with the radial seal to the tank now make it possible to close reliably against higher pressures than before. The reliability of the process is also enhanced: the balancer fitted in the closing direction prevents the double disk from closing too fast, thus reducing the risk of pressure hammers.

12.Actuator and vacuum component supplier for processing equipment solutions

EFT took great care in making them industry appropriate, operator friendly and yet sturdy enough to withstand some pretty rough treatment. We made sure that our pneumatic actuators are not spring loaded, they all are machined from 304 Stainless Steel and are designed to withstand some dings and drops. All actuators have a position indicating shaft that extends when the valve is open (for visual confirmation of valve position) and contain as few o-rings and seals as possible which require very simple maintenance on an annual basis. Additionally, to prevent any galling, we machine all our actuator bodies out of 304 Stainless Steel, All EFT actuators meet 3A requirements and can withstand operating pressure of 250 psi and operating temperature of 135° C (or 275° F).

13.Butterfly Valve and vacuum component supplier for processing equipment solutions

Butterfly valves are relatively straightforward on/off routing valves with a substantial opening area and low flow resistance. Where hygiene standards are important, these are ideal for use with low and medium-viscosity liquids.

EFT butterfly valves have proven their worth in process plants with different types of processes. EFT not only offers seat valves but also a butterfly valve series which fully satisfies increasingly higher market demands with respect to functionality, safety and cost-effectiveness. EFT butterfly valves are versatile and ensure smooth production processes, whether in production, cleaning or energy management applications in the beverage and food industries, in breweries, in the dairy processing industry or in the pharmaceutical, biotechnological, fine chemicals, cosmetics and health care sectors. What counts are the quality of the final product and the efficiency of the production line.

EFT butterfly valves are pointing the way – the development is based on the latest findings in process technology – in compliance with international standards.

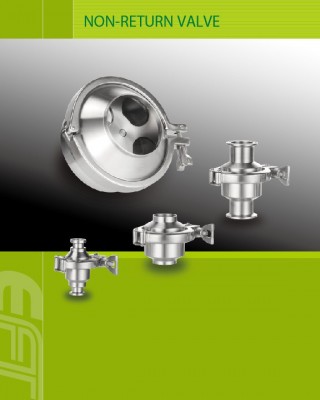

14.Non-return Valve and vacuum component supplier for processing equipment solutions

Stainless steel non-return valve for reverse flow protection. Ideal for pump outlets, general process, filling lines and backflow prevention service. EFT non-return valves specially designed for use in stainless steel pipe installations, EFT non-return valves prevent the reverse flow of fluids. Widely used in various processes throughout the sanitary industry, these standard non-return valves are safe and highly reliable. EFT non-return valve design is based on the application of an external magnetic field to close the shutter, thus interrupting the backflow inside a pipe. This innovative principle guarantees a degree of reliability which the classic spring system cannot provide.

15.Sight Glass and vacuum component supplier for processing equipment solutions

EFT's sight glasses are designed for visual inspection of media inside pipes and/or inspection of pigs in product recovery systems. The Borosilicate glass inside the housing is fixed without any tension and does resists hard pressure and vibration shocks.

EFT's sight glasses are accurate gage glasses that permit direct distortion-free visual inspection of process conditions, products, liquid levels and cleaning inside vessels used in the dairy, food and beverage, personal care and biopharm industries.

16.Sample Cock Valve and vacuum component supplier for processing equipment solutions

The sample cock valve has a fixed handle and is manually operated. Samples are taken from the bottom outlet. In closed position after sampling, the cock drains out completely so that no product remains inside the cock.

On tanks and pipework. The sample cock should be placed directly at the sampling place with minimum distance to the product.

Mounting sockets in stainless steel AISI 316L for welding into tanks and pipework are available with material certificate.

Maintenance the plug of the sample cock must be lubricated with foodgrade grease when the cock is included in CIP of vessel or pipeline. Hand tools may not be used on the sample cock.

17.Safety & Relief Valves and vacuum component supplier for processing equipment solutions

Safety & Relief valves

18.Ball Valve and vacuum component supplier for processing equipment solutions

Sanitary ball valves feature a full-bore design that enables full fluid flow with minimal pressure drop, making them ideal for handling viscous liquids or liquids containing particles in the food, beverage, chemical and pharmaceutical industries.

19.Union and vacuum component supplier for processing equipment solutions

Union

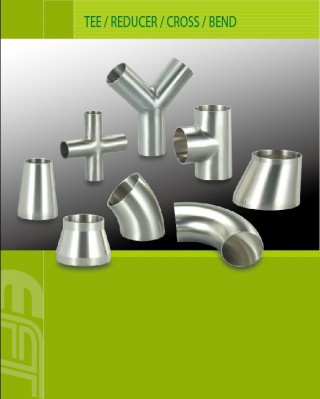

20.Tee / Reducer / Cross / Bend and vacuum component supplier for processing equipment solutions

Tee / Reducer / Cross / Bend

21.Clamp and vacuum component supplier for processing equipment solutions

Clamp Style Fittings are most popular for easy assembly and breakdown of process lines and equipment. EFT offers Clamp Fittings in 304 materials in 3/4" through 12" sizes.

Gaskets for Clamp Fittings are available in several different materials, EPDM, Silicone, Vition®, and Viton®. Lightweight and heavy-duty clamps complete the unions. EFT’s Clamp Fittings meet all 3A requirements.

22.BPE and vacuum component supplier for processing equipment solutions

ASME BPE Fittings serves the needs of those involved in the BioProcessing, Pharmaceutical, and Personal Care Product industries.

The ASME BioProcessing Equipment (ASME BPE) Standard provides designers and process engineers with a reliable and measurable way of specifying Hygienic Tubes, Valves and Fittings for use in High Purity applications such as Water-for-Injection (WFI), clean steam, ultrafiltration, etc.

EFT specialises in fabrication for the pharmaceutical and biotech industries, designing and manufacturing in accordance with ASME BPE principles. We also supply a range of tube fittings and components which are compliant with the ASME Bioprocessing Equipment Standard.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products