Stainless steel forged wine valves

Forged wine valves – solid. Zero defect production. 4bar pressure tested.

Stainless steel forging - stronger, better response to heat treatment, high density, high quality with finishing work.

French winemaker seeks manufacturing solutions in Taiwan: forged stainless steel wine valves

Many winemakers are requiring forged wine valves to replace the ones made using low pressure casting, to reduce contamination risk. For some companies that make 400,000 to 450,000 tons in a season, high wine quality is expected. In Taiwan, there’s a stainless steel vacuum component supplier who has taken one-step further and started using forging technology to make stainless steel wine valves. Today, Everfit Technology (EFT)'s forged wine valve is meeting zero defect production and allowing wine-making companies to produce fine wines.

One day, one of the leading wine valve and wine making equipment supply companies in France contacted EFT to consult with them about their wine valves. They used to buy low casting valves, however, the low quality valves brought many complaints and returns. They realized low casting might be cheaper at the beginning when comparing prices, but in the end it results in a great loss. Thus, an alternate solution is needed.

Knowing EFT has a forging factory, they flew to Taiwan for a visit. The client asked for a wine valve that would pass 3BAR pressure test. (actually valve pressure is tested up to 4BAR when conducting tests) EFT claimed that Double-sided welding would be performed to enforce strength, and that teflon and all other accessories are FDS certified.

To test the wine valve‘s pressure tolerance, EFT specifically designed a test equipment to test the valve, and purchased a world-renowned German-made pressure gauge to prove its accuracy. For every wine valve, there are three stages of leakage test to ensure high performance, and each process is strictly followed.

-

Stainless Steel Wine Valve Made From EFT:

- 20kg stainless steel is used for valve body.

- Precise positioning between parts - ball valve and valve body.

- Teflon is applied for tightness with great torsion.

- Double sided welding to assure shape quality.

- Anti - dust, anti-contamination.

- Self-developed leakage test equipment.

- Passed 4-BAR pressure test by the client.

- German world brand pressure gauge.

- Each stainless steel wine valve is 100% tested.

- One-stop stainless steel forging service.

![]() ”Companies always contact us after experiencing the results of the low casting process. Low pressure casting is cheaper but not after dealing with all the problems. The dilemmas usually include the low quality of valves; low casting supplier can’t meet the deadline, high cost for quality control and high defect rate. ” said Bert Huang, the vice president of EFT.

”Companies always contact us after experiencing the results of the low casting process. Low pressure casting is cheaper but not after dealing with all the problems. The dilemmas usually include the low quality of valves; low casting supplier can’t meet the deadline, high cost for quality control and high defect rate. ” said Bert Huang, the vice president of EFT.

"The biggest advantage to work with EFT is the access to our own forging factory. It allows EFT to provide one stop service from heat treatment, forging and finishing, and eventually to control the entire expense to lower the cost without sacrificing quality." said Tom Chang, the vice president of EFT.

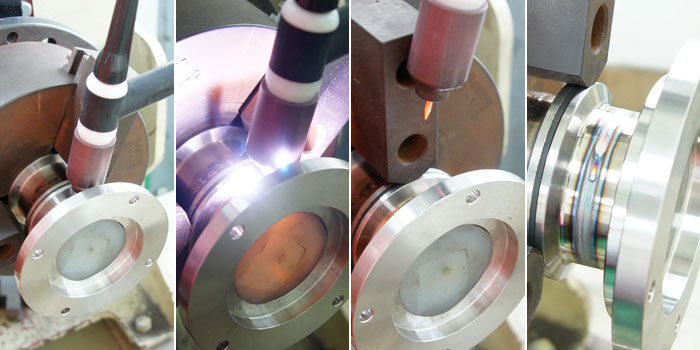

Welding between two components

When conducting low pressure casting, defects occur for many reasons. For example, design part’s various thickness can cause different cooling time and therefore result in shrinkage and porosity. The low casting defects include blows, scars, blisters, scabs, misruns, cold shutting. hot tears, cracks, etc. When it happens, impregnation treatment is applied even though it’s not permitted in many industries.

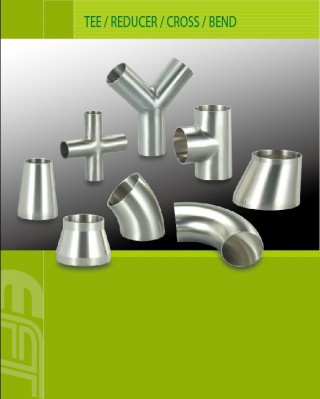

Forging is a stronger, better response to heat treatment, high density, high quality with finishing work, and delivers a degree of structural integrity that is unique compared to other metalworking processes. Forging avoids the internal voids and gas pockets that can weaken metal parts. Stainless steel forging is suitable for semiconductors, food, pharmaceutical companies that ask for rigorous processing procedures.

As a result, every wine valve is state-of-the-art, tested and FDA certified. Currently EFT is working on this French company's 2nd order.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products