Taiwan absolute vacuum components design winning Japanese trust

CIP/SIP System, world-class vacuum fitting

Semi-conductor vacuum components, processing equipment for your tough requirement

Eight-year excellent vacuum component work for a Japanese company

EVERFIT TECHNOLOGY CO., LTD. (EFT) has served a Japanese company well with their high quality semiconductor vacuum component for eight years. Since Japanese companies are famous for being meticulous and strict, how did EFT meet their requirements and survive in the competitive market these days?

Semi-conductor stainless steel vacuum components & Fittings requirement

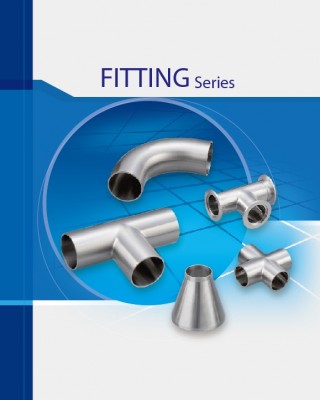

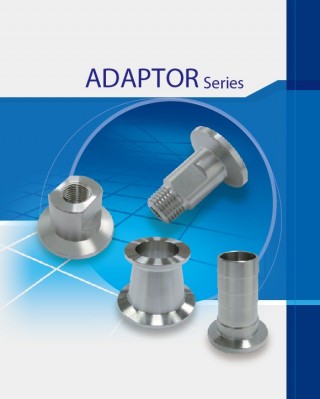

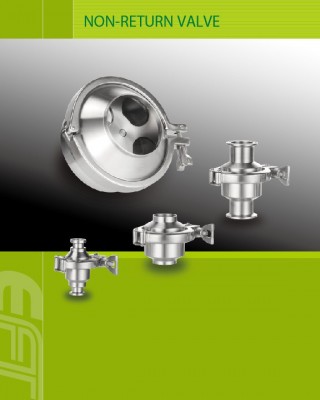

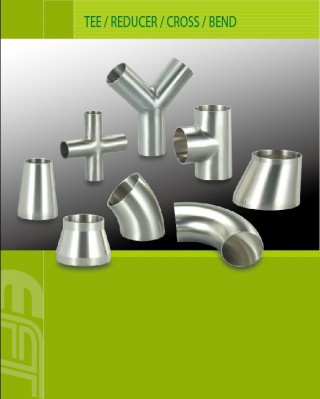

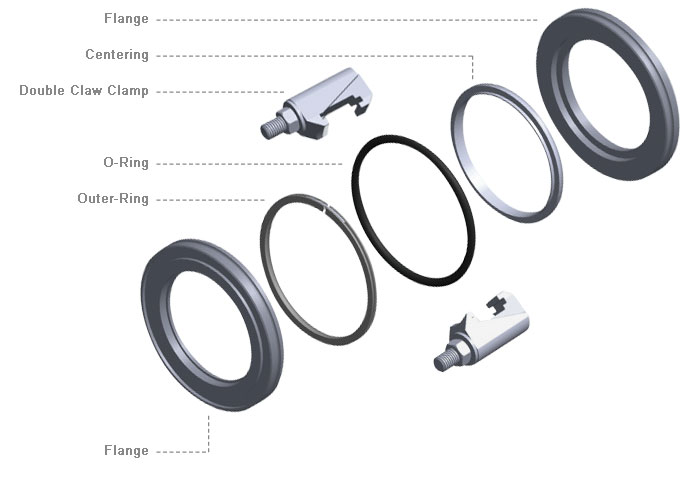

For the semiconductor industry, semiconductor device vacuum component is rigorously required to be vacuum engineered in order to process in an aseptic environment. Since toxic gases are applied during process, sterilized stainless steel parts such as flanges, adaptors, clamps, bellows and vacuum fittings should be ISO certified. In addition, pipe fittings should be seamless; assembly, cleaning and packaging should be done in a clean room.

For food processing equipment, pipes and fittings have to allow high acidity. However, when manufacturing semiconductor devices, processing equipment that has high pressure tolerance and zero defect production is critical. For excellent aseptic equipment, it would not only increase equipment efficiency but also reduce maintenance.

Japanese companies tough requirements for vacuum Components & fittings

It is frequently said that Japanese companies are very strict about quality, and FET experienced that themselves. When the Japanese company was searching for a partner to expand their production capability and to broaden the market, their specific requirements resulted in lots of manufacturers being turned down. "They requested stainless steel vacuum fitting samples, and when they flew over to check out the vacuum component samples, they had markers in hand to circle the dust." the vice president Tom Chang recalled. As a result, the company visited EFT five times before making the orders. For the half year, they were just reassuring EFT's capability, and their picky requests made EFT pursue the best. The two companies now cooperate on vacuum fittings, including welded bellows, formed bellows, flexible tubes, etc.

To control the vacuum components & fittings quality, all stainless steel coming from Taiwan's largest steel companies, namely Gloria Material Technology Corporation and Walsin Lihwa Corp. includes material reports, and when they arrive at the plant, all stainless steel is tested using SPECTRO iSORT. EFT has expanded their plant by establishing a mold design and development division. The semiconductor vacuum component mold design team utilizes the latest technology in hardware and software to design molds. With plenty of mold design experience, every mold has improved cycle times and ultimately keeps costs down. EFT has procured more machines to increase the production capability, including pressing machines, sawing machines, drilling machines, CNC machines, ultrasonic and RO water cleaning machines and a custom made non-oxygen welding machine.

The stainless steel vacuum component quality is assured by executing first production examination, every two hours' onsite inspection by supervisors, lab testing using suitable testing equipment including Crysta-Plus M 776, Mitutoyo contracer contour measuring instrument, optical comparator and TECLOCK sylvac. EFT also implemented a class 10,000 clean room to meet vacuum components' 100% aseptic environment requirements.

ISO Flange connection with Clamp

Cleanroom (class 10,000) For High Standard Vacuum Component:

Class 10,000, ISO certified cleanroom for hygienic vacuum components

For semi-conductor, pharmaceutical, bio-technology and food processing industries, stainless steel vacuum components are required to be purified and particle-free. Therefore, EFT has set up a cleanroom that is equivalent to ISO standard. In the cleanroom, vacuum fittings will be cleaned; the assembling and packaging processes will be done in the room before leaving the room.

Eventually, the Japanese company was really satisfied with EFT's quality work, and every month they have been receiving orders from them over the past eight years. Because of the high quality stainless steel vacuum fittings that EFT fabricated for them, it also attracted other Japanese and Taiwanese semiconductor companies' attention. One of the world's leading semiconductor device suppliers from Taiwan asked EFT to become their vacuum fitting OEM supplier after several visits. Later, EFT has broadened their service range from OEM, ODM to custom vacuum component and process equipment supply.

![]() The Japanese company was established in 1984. They are specialized in processing piping design, construction, process equipment manufacturing including welded bellows, vacuum pumps, vacuum component and accessories supply.

The Japanese company was established in 1984. They are specialized in processing piping design, construction, process equipment manufacturing including welded bellows, vacuum pumps, vacuum component and accessories supply.

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products