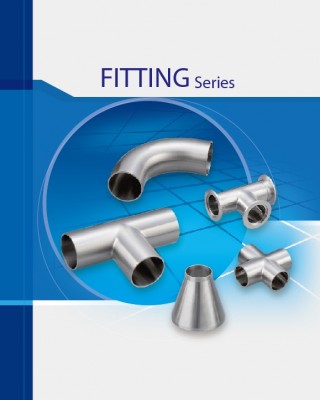

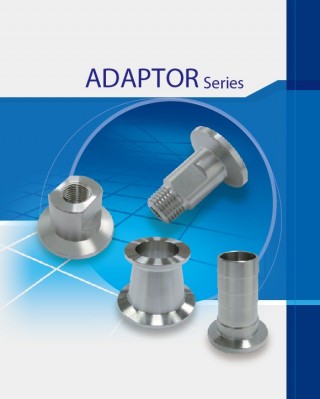

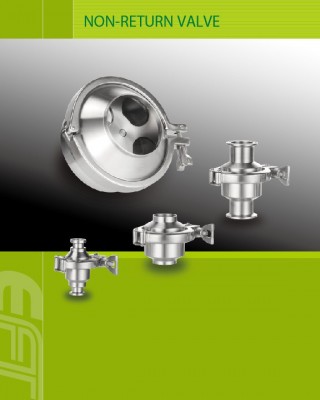

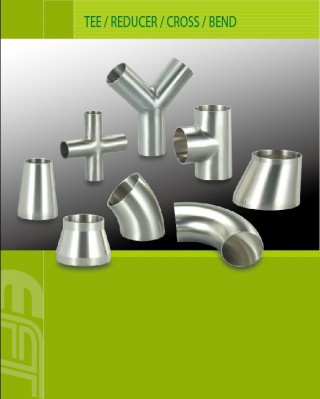

Vacuum component and fitting supply

ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI vacuum components

Cleanroom. SIP/CIP system test. International standard vacuum fittings

World standard vacuum component plant to meet your needs

EVERFIT TECHNOLOGY CO., LTD. (EFT) is a full service supplier dedicated to provide a wide range of stainless steel vacuum components, valves and product solutions for various fields including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering. EFT has a 5,500 square meter plant that is capable of performing mold design and manufacturing, heat treatment, casting, forging, plating, drilling, milling, CNC machining, cleaning, welding, assembling, and packing in a class 10,000 cleanroom. EFT is capable of delivering all stainless steel components comply with ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI criteria.

Stainless steel material report and test (SPECTRO iSORT):

Made in Taiwan high quality stainless steels with reports and tests

All of the stainless steel is procured from Taiwan's largest steel companies; they are Gloria Material Technology Corporation and Walsin Lihwa Corp. Even though made in Taiwan stainless steel is more expensive, its EFT’s determination ensures the steel quality. Besides material reports provided by the steel companies, when the steel arrives, it is tested using SPECTRO iSORT to assure its purity and that it is radiation-free. As soon as they are tested, they are tagged in various colors for identification.

Stainless steel vacuum component research and development (R&D) team:

EFT elites have been designing outstanding stainless steel valves and vacuum components that meet international standards

EFT has a team of six engineers with marvelous engineering experience in various industries including semi-conductor, pharmaceutical, bio-technology, food processing and structural engineering, and that's why they are capable of maintaining the partnership with international buyers from the U.S., France, Germany, Japan, U.K., Italy and Taiwan. EFT's stainless steel vacuum components are equivalent to world-class brands such as Alfa Laval, Gemü and SODIME because they follow their design concept and system. Low tolerance means 100% vacuum fitting test, and their good principle has allowed them to become a well-known manufacturer with high quality.

Mold design and development:

Excellent mold design and manufacturing skills is a factor for making stainless steel valves and vacuum fittings

For each stainless steel vacuum component, there are at least three molds designed and manufactured for the whole process, and the mold making cycle-time is driven in part by size and complexity. To reduce mold fabrication and development cycle time, years ago, instead of having their molds manufactured elsewhere, EFT started to design and fabricate their own molds. The mold design team utilizes the latest technology in hardware and software to design molds. With plenty of mold design experience, every mold has improved cycle times and eventually keeping the cost down.

Sawing machine:

Sawing machine for various types of stainless steel pipes and bars

In EFT, there are more than five 100% automatic sawing machines which are capable of working 24 hours non-stop. The high capability allows EFT to accept big orders and meet the deadlines. "One time they received an order for 500,000 stainless steel valves, the sawing machines were working 24 hours non-stop for days." The manager of EFT recalled.

High-frequency induction hardening machine for hot forging:

Stainless steel vacuum components and valves hot forging

High-frequency induction hardening machine is heating equipment for a wide range of industrial applications, especially for stainless steel vacuum pipes and bars. With the machine, the stainless steel vacuum pipes and bars are heated up to more than 1,000 degrees Celsius in a minute, once they are heated, they are shaped immediately by pressing machines.

Gas burner for hot forging:

Gas burner machine is heating equipment for flat stainless steel plates.

Pressing machine:

Vacuum fitting pressing process

For compressive forces, EFT has 200, 300 and 800 tons stamping pressing machines to handle a large quantity stainless steel vacuum equipment orders. The pressing machines are applied based on the stainless steel component’s weight range.

Upright type drilling machine:

Drilling machine for making stainless steel valves, vacuum fittings, vacuum components

EFT has ten drilling machines; they are capable of drilling stainless steel valves, vacuum fittings from 12mm diameter up to 42mm. Drilling machines are for hole drilling, after drilling, the drilled stainless steel vacuum fittings are moved to the CNC machining section for extra processing.

CNC lathe machine and milling machine for stainless steel vacuum valves, vacuum fittings:

In EFT's 5,500 square-meter plant, there are 18 CNC lathe machines, 2 CNC milling machines with 4 CNC lathe machine blade change engineers, which allowed EFT to manufacture stainless steel vacuum components from 3/8 to 8 diameters with 80,000 to 100,000's production capability per month.

CNC milling machines for vacuum components

Since every stainless steel vacuum fitting requires particular machining processes, for components that may need CNC machining or butterfly valves request milling, they are all arranged by the project manager based on their characteristics. All of the vacuum components can be requested for extra drilling, milling and cutting processes to meet the goals. Especially for high pressure stainless steel valves, which require high standard machining processes to achieve some challenging angles or axes.

Stainless steel vacuum component onsite inspection:

Onsite inspection with visual inspection, equipment inspection

During production, there's a card that goes along with the operator to make sure that every step is executed accurately, and the card indicates the tolerance of the stainless steel vacuum fittings, the temperature, and the number of times for rough surface grinding, etc. Supervisors are responsible to check the card and to measure stainless steel vacuum components every two hours regardless of the different stage of production. The stainless steel vacuum component is tested at the lab for its precision in order to prevent any defeat production.

Ultrasonic and RO Water cleaning process:

After CNC machining, each vacuum part has to go through a cleaning process to get rid of grease, dust, oil, etc. The whole process contains six sections including ultrasonic cleaning (container 1), ultrasonic cleaning (container 2), hot RO water cleaning (container 3), hot RO water cleaning (container 4), hot RO water cleaning (container 5) and dry (container 6).

Ultrasonic and RO water self-cleaning process for stainless steel vacuum components

RO water is one kind of purified water that removes molecules and ions using a high pressure technology. To avoid the unnecessary pollution from underground water, stainless steel vacuum components are cleaned using the most purified water - RO water.

To prevent friction during cleaning, there are custom-made racks to place each of the components separately.

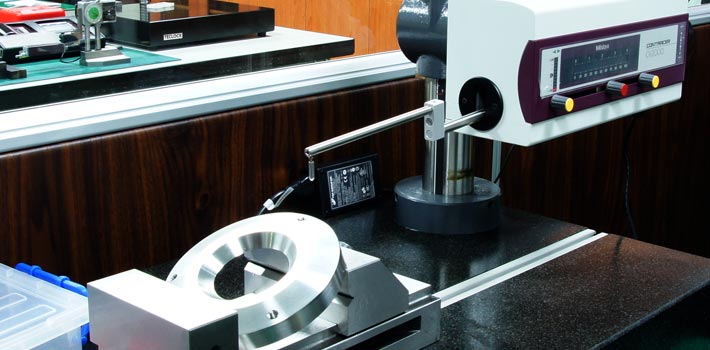

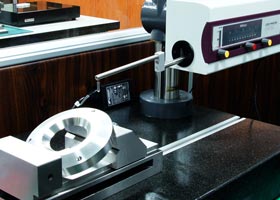

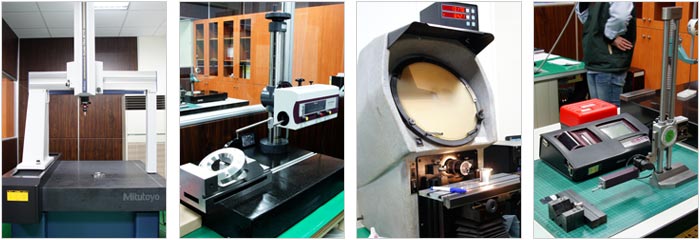

Gauge and measuring tool for stainless steel vacuum components (valves, flange, stud clamp, pipe fitting):

There is testing equipment for individual stainless steel valves and vacuum fittings in EFT's testing lab and it is temperature controlled.

-

Crysta-Plus M 776:

- Crysta-Plus M 776 is easy-to-use coordinate measuring equipment that is used particularly for bolted flanges. The needle is able to hook up the hole and calculate its measurement accurately.

-

Mitutoyo contracer contour measuring instrument:

- The XY plotter contours the surface of stainless steel vacuum component and illustrates the distances and routes on the computer or other display units. It is suitable for measuring R and C angles.

-

Optical Comparator:

- Optical Comparator: Optical Comparator is an easy-to-use piece of equipment that can assist you to measure stainless steel vacuum fittings as soon as you place them on the platform. Readings are via .00005"/.001mm precision glass scales; it is suitable for measuring the thickness and oblique angle of components.

-

TECLOCK sylvac:

- TECLOCK sylvac can assist you to measure the depth of the vacuum components.

(From left to right)

Crysta-Plus M 776 (manual floating type coordinate measuring machine for stainless steel flange.)

Mitutoyo contracer contour measuring instrument.

Optical comparator for measuring.

TECLOCK sylvac.

Stainless steel vacuum component welding:

EFT custom made none-oxygen welding machine for prefect welded vacuum components

Custom-made welding machine is designed and built based on EFT’s years of experience. It is a none-oxygen welding machine, and its objective is to prevent oxygen porosity. With the newly designed welding machine, welding jobs are done perfectly.

Stainless steel vacuum component electroplating:

For some alloys that contain coppers, because of their characteristics, electroplating will be applied to prevent the change of colors.

Stainless steel vacuum component polishing:

After cleaning, each stainless steel vacuum fitting is polished and wiped just like a mirror.

Stainless steel vacuum component assembly:

vacuum component assembling

EFT is specialized in making stainless steel vacuum components for the semiconductor, food processing, and pharmaceuticals sectors. For some stainless steel vacuum components, they are assembled using more than 20 parts. Some parts are imported from Germany and Japan to present the best quality to their clients. For example, the German-made spring is tested for more than 200,000,0 times without breaking, and it comes with a report to prove it.

Stainless steel vacuum component testing:

Regardless of designing and manufacturing stainless steel vacuum components for semiconductor, food processing or pharmaceutical companies, precisely made components are required by them to ensure that the whole process is accurately done without accidents. Therefore, rigorous tests are conducted including water leak test, airless test, and sight glasses are applied for the tests as well.

Stainless steel vacuum component labeling:

Ink jet printing, laser printing, dot matrix printer or impact matrix printer are doable upon client's request.

Stainless steel vacuum component packaging and shipping methods:

Every client requires different packaging methods, EFT provides dynamic packaging ways to satisfy their needs. There is PE packaging, packaging, foam packaging, net packaging, or any other environmentally friendly packaging materials. In addition, before packing, visual inspection is performed to ensure the cleanness of each stainless steel vacuum component.

Cleanroom (class 10,000) for high standard stainless steel vacuum component:

Class 10,000, ISO certified cleanroom for hygienic vacuum components

For semi-conductor, pharmaceutical, bio-technology and food processing industries, stainless steel vacuum fittings are required to be purified and particle-free. Therefore, EFT has set up a cleanroom that is equivalent to ISO standard. In the cleanroom, stainless steel vacuum components will be cleaned; the assembling and packaging will be done in the room before leaving the room.

Stainless steel vacuum component inventory:

With a 5,500 square meter plant, EFT is capable of storing more than 200 tons of stainless steel materials to cope with large and urgent orders.

FERRULE QC inspection procedure

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products