Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

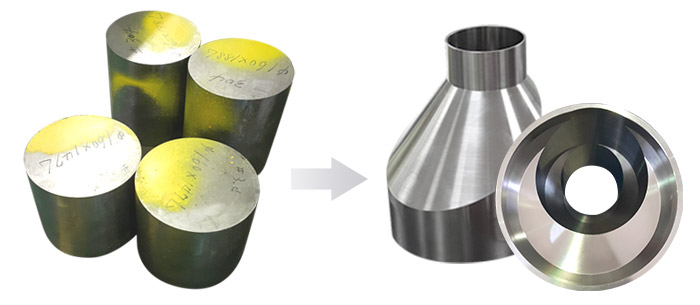

Complex shapes, double contours or relatively large vacuum components manufacturing

ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI Stainless Steel Pipe Fitting

Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

Starting from manufacturing food grade 304 stainless steel pipe fittings in 1988 at a small factory, EFT (Everfit Technology CO., LTD.) was one of very few manufacturers in Taiwan. Over the last 40 years, EFT had moved to a 5,500-meter plant due to the ramp up of their business and the workpiece's increased challenge from clients. As client's vacuum component requirement complicity increased, EFT's machining and inspection process upgraded from time to time.

Robot Arm High Technology Pipe Fitting Production

There's no more human error or manual flaw with robot arm processing.

Between the robot arm and adjustment of fixture and jig, EFT is moving toward to becoming a manufacturer of pipe fittings with high technology. With the automatic robot arm, the production cost is lowered, quality is controllable, and production capability is highly effective. There's no more human error or manual flaw.

Unlike before, each product is delivered and taken by hand. It may seem simple, but it makes a big difference when having a robot arm that is capable of produceing 20,000-30,000 pipe fitting a day. Time is money. Thus, EFT purchased a robot arm to increase the product quality and production capability. With robot arm's assistance, the employee is responsible for setting up the PLC, checking the product, changing knife/fixture and inspection.

Robotic arm has been assisting EFT meeting deadlines with great precision and accuracy, thus providing improved, consistent product quality.

With the automatic robot arm, the production cost is lowered and quality is controllable.

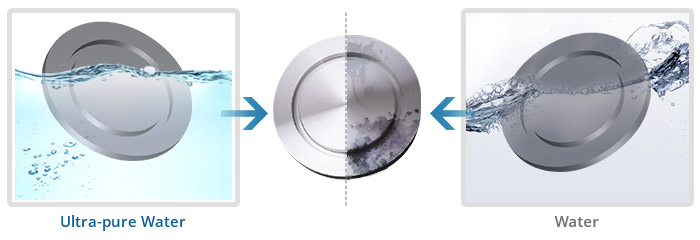

Ultra-pure Water System - Delivers the Cleanest Pipe Fitting

When the pipe components are delivered to semiconductor or food processing company's sites, each part has to be extremely clean without any microscopic dust. To do so, EFT bought a set of Ultrapure Water Systems to produce the finest water. The system is used in industries such electronics for IC manufacturing, a pharmaceutical for medicine production, cosmetics and food production.

During the machining process, dust, grease, and steel filings can remain attached to the vacuum pipe fittings. To solve the problem, there's a procedure: first, alkali cleansing, then acid treatment, followed by purified water washing, and the last would be hot air blow dry. It is to make sure the client receives the best of product, 100% clean without any particles on the surface. To see more details of Ultrasonic and RO Water Self-Cleaning Process .

Ultrasonic and RO Water Self-Cleaning System

Stainless steel filings, grease stains, oil stains or water stains are removed after using ultrasonic and RO water self-cleaning system, and the labor cost is lowered.

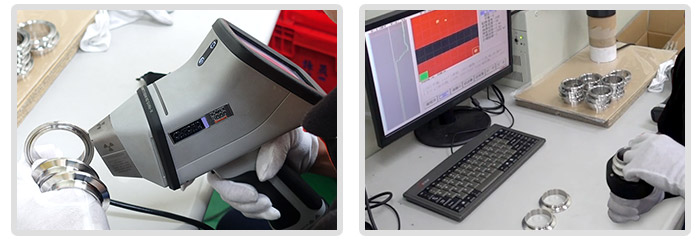

Automatic Stainless Steel Detector before Vacuum Component Delivery

When stainless steel shipments arrive, 304 or 316 are marked by color using laser guns. Before shipping to clients, every vacuum component is checked to double-check the accuracy of the steel. It is a system developed through collaboration between EFT and the equipment company. The goal is to assure 100% accuracy of steel.

The 304, 316 stainless steel comes test machine comes with two molds, each time you put a fitting on the tool, it makes a distinct sound when it's not what the parameter is set for. Because of this equipment, 304 and 316 are detected quickly, which saves time and cost. Since then, metallurgical analysis always resulted in precisely what material is expected.

304 and 316 stainless steel detector system is designed to ensure its material accuracy.

ISO 9001:2015 Certificate

EFT has been gaining recognition internationally because of their high-quality pipe fittings, even though buyers came from all over the world with high standards. Tasks like multiple welding on a single cavity (PC) pump, pipe tee with a particular pulling technique, valve component that needed special machining using CNC and milling machine, cleanroom process , 316L eccentric reducer weighted 30 kg (6 inches) that required CNC machining and non-central valve components forging , valve actuator spring that required long-term test, or vacuum component requested to meet ISO, EN11435, DNV, TSSA CRN, BPE, 3-A SSI criteria.

EFT's vacuum components are sold worldwide, including in Germany, the U.S., the U.K., France, Japan and Israel. Industries ranging from semi-conductor, pharmaceutical, environmental management system, food processing to biotechnology, which requires seamless, purified, precise and particle free components. To meet international buyer's particular specifications for steel fittings, stainless steel 304 and 316 Ti was imported from Italy, France, and Korea to improve its machining performance. 316 Ti is cut 100% accurately by new CNC automatic circular sawing machines because of its material characteristics. Welding precision was taken care of by robot arms. Equipment was purchased to improve machining performance. Software, gadgets, and molds were developed to speed up the material test and production capacity. Overall, the engineering team was terrific, averaging over 20 years' engineering experience that has allowed each engineer to come up with solutions with great flexibility.

Complex shapes, double contours or relatively large components were challenging, but EFT resolved problems step by step with seasoned experience. Whatever it takes for EFT to achieve client's goals, such as manufacturing 316Ti ferrules for a fluid connector, eccentric reducer for pharmaceutical's medicine process, robotic welding for pipe tee, valve component that involves tough machining job for the non-central angle stub flange section, etc., EFT's relentless hard work and the zero tolerance on each pipe component's specification is the main reason for today's success.

Large size stainless steel 316L, 30kg and size 6 inches eccentric reducer is built meeting ASME BPE standards.

Accuracy is always the objective, regardless of whether it's for tooling and machining process or product inspection. At the lab, test equipment is provided, but the precision would depend on the standard of machinery. Beginning with food-grade 304 pc pump part to BPE semiconductor piping and today's 316Ti stainless steel pipe fitting for oil piping, for a component that is large, has eccentric circles or with an internal diameter, the regular testing equipment can no longer fit for test requirements. In 2017, procurement was made to improve the quality of stainless steel fittings, whether its ferrule, vacuum flange, compressible bellow connection, pipe fitting, adapter or diaphragm valve, the precision is assured. EFT is one step further toward to meeting ISO2015 international standards.

IM Series Instant Measurement System - 100% Pipe Fittings Specification Precision

IM Series Instant Measurement System

Every test machine has its functionality; comparator is suitable for outside diameter, height gauge works for inner and outer diameter, roundness tester for inner diameter, and coordinating measuring machine is for stainless steel flange. Instead of using ruler and projector, which takes time to get it done, EFT purchased an IM Series Instant Measurement System to speed up the process, as well as to increase its accuracy.

Normally it takes 3 minutes to finish the measurement for one product. With the regular IM Series Instant Measurement System, once the pipe fitting is scanned and the parameter is set, the scanning takes less than 10 seconds. The equipment measures up to 99 dimensions in seconds, including parallelism, concentricity, roundness, straightness, true position, full profile and more. ( read article: World Standard Vacuum Component Plant To Meet Your Needs)

ARTICLE SECTIONS

- Everfit Technology's progressing cavity (PC) pump part meets Japan world class standards with 100% precision

- Everfit Technology's Pipe Fitting Robot Arm Production Exceeds World-Class Client Expectations

- EFT innovative 316Ti stainless steel pipe fitting machining technology exceeds German leading fluid connector manufacturer's expectations. Everfit Technology CO., LTD.

- Cost-saving, state of the art pipe tee made by Everfit Technology wins an Israeli client's order

- Everfit Technology's High-End Vacuum Component Sells to Semiconductor Industry in Japan

- Taiwan absolute vacuum components design winning Japanese trust

- Pharmaceutical sampling valves supply

- Germany, Japan, England imported valve actuator components

- ISO, EN11435, DNV, TSSA CRN, BPE certified diaphragm valve

- Vacuum component and fitting supply

- Stainless steel forged wine valves

- Multiport stainless steel valves from Taiwan

- One-Stop forging service valve provider - EFT

- EVERFIT TECHNOLOGY CO., LTD. (EFT)

- Contact a vacuum component and valve supplier for processing equipment solutions

- Send inquiry to a Taiwan vacuum component supplier

- EVERFIT TECHNOLOGY CO., LTD. (EFT) Privacy Policy

PRODUCT CATEGORY

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Search related products